CNC Turning

BENEFITS

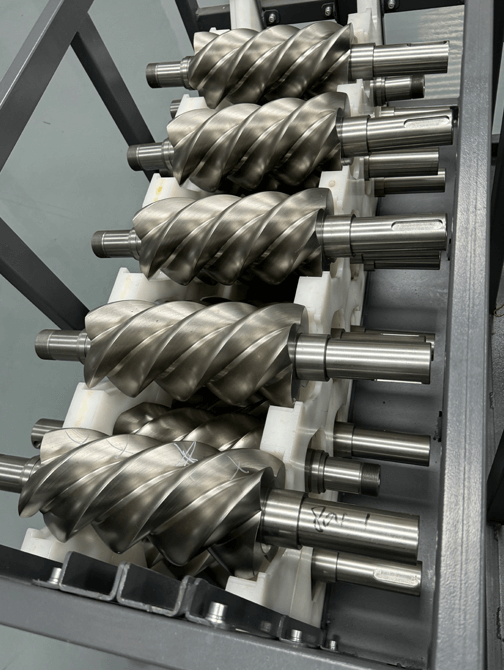

CNC Mill-Turn Center is the only machining equipment that can complete all cutting steps in one clamping. It has 9-axis linkage cutting. The arc surface contour cutting can be done by turning and milling (turning instead of milling), which is more than twice the efficiency of 5-axis milling. Up to three tools can be used for cutting at the same time, saving more than 200% of working hours, and the cutting accuracy is less than 0.003mm. It also has gear turning/internal and external grinding.

FEATURES

CNC Mill-Turn Center is a powerful tool for processing high-precision and complex transmission shaft parts and polyhedron parts.

BENEFITS

Swiss Turning is synonymous with the manufacturing of tiny precision parts. For small, diameter <1.00mm, and slender shaft parts, no other cutting process is more perfect than Swiss Turning. Its special clamping principle allows the tool to always fit the clamping guide sleeve for cutting, and the part will not be deformed by the cutting force.

FEATURES

Modern Swiss Turning has dual spindles, supports axial end face and warp surface and geometric structure milling, and has a tool capacity of more than 30x. It has become the main production equipment for tiny precision parts, with extremely high precision and cost-effectiveness, making the parts lighter, more compact and more efficient.

BENEFITS

By de-tracking production capacity from the number of employees required, manufacturing units can improve efficiency by moving human resources down to the assembly line. It is well known that manual assembly lines are more efficient in high-volume environments because the assembly of products is highly complex and requires specialized skills that cannot be replicated by machines.

FEATURES

In addition, high-precision component turning makes it possible for parts to fit together seamlessly, allowing the assembly line to flow freely without interruption.

Applications & Grades

Precision turned components are manufactured by turning cylindrical parts on a CNC lathe or machine. Cutting tools, end mills and drills are then used to cut the component to the desired size and shape, resulting in high-precision components that meet the performance requirements of demanding commercial applications.

- Turbine water pump

- Motor shaft & Screw

- Medical testing equipment

- Energy photoelectric valve body