What is the significance of casting quality control? How to control it?

Casting quality control is a key step to ensure the quality of castings. Through reasonable quality control, product quality can be effectively improved and customer needs can be met. In actual operation, adjustments and optimizations should be made according to specific circumstances to achieve the best quality control effect.

This article will explore the significance of casting quality control and the specific aspects of quality control.

Table of Contents

1.The significance of casting quality control

(1) Improving product performance and service life:

High-quality casting products can improve product service life and reliability, reduce failure rate, and thus improve customer satisfaction and loyalty.

(2) Ensuring production efficiency and reducing costs:

Effective casting quality control can reduce the generation of scrap and defective products, increase the first-time pass rate, and reduce production costs. At the same time, it reduces the number of rework and recasting, shortens the production cycle, improves production efficiency, and helps companies quickly respond to market demand.

(3) Enhance corporate competitiveness:

In the fierce market competition, high-quality casting products can win more market share and customer trust for companies. High-quality casting products can establish a good brand image for the company and enhance the company’s market position and competitiveness.

(4) Ensure production safety:

The casting process involves dangerous factors such as high temperature, noise, and dust. Effective quality management can ensure operational safety, reduce work-related accidents, and protect the personal safety of employees.

(5) Promote technological progress and innovation:

Casting quality control requires enterprises to continuously optimize production processes and introduce new technologies and equipment to improve the company’s technical level and innovation capabilities.

(6) Meet environmental protection requirements:

Casting quality control also includes the control of environmental pollutants generated during the casting process to ensure that the company complies with environmental protection regulations and achieves green casting.

(7) Maintain corporate reputation and customer relationships:

High-quality products help maintain the company’s reputation, establish long-term customer relationships, and promote the stable development of the company.

2.Aspects of casting quality control

(1) Raw material control

Casting raw materials are the basis of casting product quality. High-quality materials that meet the requirements must be selected and strictly inspected for incoming goods. For example, raw materials such as metals, sand molds, and coatings used for casting must undergo chemical composition analysis and mechanical property tests to ensure that they meet design requirements. In addition, reasonable storage and use of raw materials to prevent materials from being contaminated or deteriorating are also key to ensuring casting quality.

(2) Process control

The casting process is an important factor affecting product quality. Process control includes formulating a reasonable casting process flow, controlling parameters such as pouring temperature and cooling speed. For example, key process parameters such as melting temperature, pouring speed, and cooling time need to be strictly controlled to ensure that each parameter meets the design requirements.

(3) Equipment control

Casting equipment is the key to realizing the casting process. Equipment control includes equipment selection, maintenance, and upkeep. For example, melting equipment, pouring equipment, sand processing equipment, etc. need to be regularly inspected and maintained to ensure their normal operation and avoid production problems caused by equipment failure. At the same time, necessary disinfection and cleaning of equipment to prevent cross contamination is also an important measure to ensure product quality.

(4) Environmental control

The casting environment is another aspect of casting quality control. Environmental control includes controlling parameters such as temperature, humidity, and cleanliness of the workshop. Keep the workshop clean and tidy, clean and disinfect it regularly, and avoid problems such as dust and oil pollution that affect the quality of castings. In addition, studying the impact of environmental conditions such as climate, humidity, and temperature on casting quality and taking corresponding measures in the process plan are also important means to improve casting quality.

(5) Inspection and control

Inspection is an important means of casting quality control. A strict inspection plan should be formulated, and the products should be inspected at the beginning, in the process and at the end. For example, the first casting of each batch should be strictly inspected to ensure that it meets the design requirements; inspection should be carried out after each process link to timely discover and solve potential problems; and final inspection should be carried out after production to ensure that all castings meet the quality requirements. Unqualified products should be reworked or scrapped in time to avoid affecting the overall quality.

(6) Continuous improvement

Continuous improvement is the key to ensuring the quality of casting products. By collecting and analyzing quality data, we can find out the existing problems and improvement points, and take corresponding measures to improve them. In addition, regular review and update of the casting quality control system to adapt to changes in market and customer needs is also an important way to improve product quality.

Summary:

In short, casting quality control is a necessary means to ensure the quality of the final product. By controlling raw materials, processes, equipment, environment, inspection and continuous improvement, the quality and performance of casting products can be effectively improved.

3.Specific measures for some important processes of casting quality control

(1) Sand mixing/molding process

1) Key control points: composition, humidity, compactness, etc. of the molding sand.

2) Specific measures: formulate strict sand mixing and molding operating procedures, control the ratio and performance of the molding sand, and regularly test the water content and strength of the molding sand.

(2) Melting/pouring process

1) Key control points: chemical composition of the molten metal, pouring temperature and speed.

2) Specific measures: formulate a reasonable smelting process according to different casting requirements, control the chemical composition and temperature of the molten metal, ensure a smooth pouring process, and avoid defects such as pores and shrinkage holes.

(3) Cleaning process

1) Key control points: surface quality and dimensional accuracy of the casting.

2) Specific measures: select appropriate cleaning tools and methods to avoid damage to the casting, and conduct strict inspections on the cleaned castings to ensure that the surface finish and dimensional accuracy meet the requirements.

(4) Heat treatment process

1) Key control points: heat treatment process parameters.

2) Specific measures: According to the material and performance requirements of the casting, formulate a reasonable heat treatment process, control the heating temperature, holding time and cooling rate, and ensure that the casting achieves the required mechanical properties.

(5) Casting inspection process

1) Key control points: internal and surface defects of the casting.

2) Specific measures: Use advanced testing equipment and methods to conduct comprehensive inspections of castings, including dimensional inspections, surface inspections, non-destructive inspections, etc., to ensure that the castings meet quality standards.

(6) Connection and coordination between processes

1) Key control points: coordination and coordination between processes.

2) Specific measures: Establish a complete process conversion management system to ensure smooth connection between processes, avoid quality problems caused by improper coordination between processes, and implement effective casting quality control measures.

Summary:

Casting quality control is the core link in the product production process. Casting quality control is not only the inspection of the final product, but should run through the entire production process. Every step requires strict management and control.

4.LVXUN’s metal casting quality control methods:

We will conduct rigorous testing on castings to ensure that the final product meets quality requirements. The following are LVXUN’s quality inspection methods:

(1) Appearance inspection

Appearance inspection is the most basic casting quality inspection method. It mainly relies on the naked eye or simple tools such as magnifying glasses to observe the surface of the casting to determine whether there are obvious defects, such as cracks, pores, slag inclusions, cold shuts, shrinkage holes, flash, burrs, etc.

This method is simple to operate and low in cost, but it mainly relies on the operator’s experience and cannot detect internal defects or minor flaws. It is suitable for preliminary inspection and rapid screening.

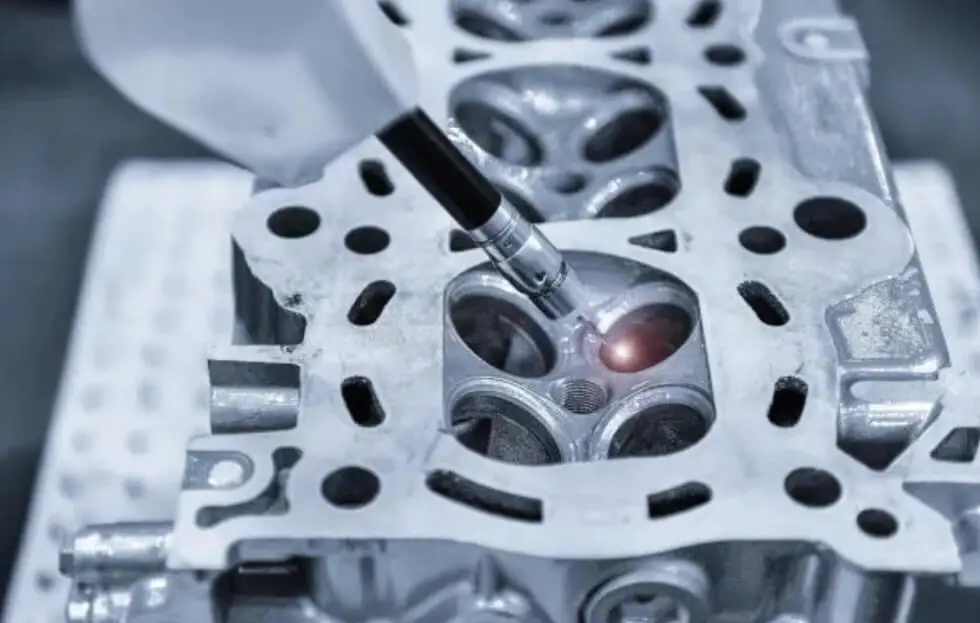

(2) Coordinate measuring machine inspection (CMM)

Coordinate measuring machine is a high-precision dimensional inspection equipment and a casting quality control method used by most companies.

This method uses a probe to obtain the coordinates of the geometric points of the casting in three-dimensional space, and then compares and analyzes them with the CAD model or technical drawings.

It is suitable for measuring the size, shape and position tolerances and geometric features of complex castings. Its advantages are high precision, high degree of automation, and objective and reliable results. It is often used for quality control of high-end castings, such as aviation, automotive power systems and other fields.

(3) Optical comparator comparison

The optical comparator is a non-contact optical measurement device that magnifies the contour of the casting and compares it with the standard template or CAD contour to determine whether its size and shape contour are qualified.

This method is suitable for contour detection of small and medium-sized parts. It has the advantages of being intuitive and easy to operate. It is especially suitable for batch detection of castings with high consistency, but has limited capabilities in high-precision three-dimensional detection.

(4) X-ray scanner inspection

X-ray scanning is a typical non-destructive testing method, mainly used to detect whether there are invisible defects such as pores, shrinkage, slag inclusions, cracks, etc. in the casting.

By penetrating metal materials and imaging by X-rays, internal structural abnormalities can be clearly reflected.

This method is suitable for castings with complex structures and high reliability requirements, such as automobile wheels and aviation parts. Its disadvantages are high equipment cost and radiation protection requirements for operators.

(5) Ultrasonic testing machine inspection

Ultrasonic testing is a method of detection using high-frequency sound waves. When the ultrasonic wave encounters a defect (such as a crack or pore) inside the casting, it will be reflected. By analyzing the echo signal, the defect location and size can be determined.

This method has accurate data and high technical content. It is especially suitable for detecting internal defects of medium-thick wall metal castings, but it requires high skills of the inspector and is not suitable for castings with complex shapes or irregular surfaces.

(6) Surface roughness test

The surface roughness tester is used to measure the microscopic roughness of the casting surface, which is often expressed in parameters such as Ra and Rz.

The instrument slides along the surface through the stylus. When it senses the undulations on the casting surface, it converts it into an electrical signal, thereby analyzing the roughness value.

Surface roughness directly affects the appearance quality, subsequent processing performance and matching accuracy of the casting. This method can quantify the surface quality of the casting and is often used for the detection of precision castings, such as valve bodies, gear housings, hydraulic components, etc.

5.How does LVXUN control the airtightness of aluminum castings?

When aluminum castings are used in sealing and pressure-bearing scenarios (such as hydraulic systems, fuel systems, compression equipment, etc.), airtightness control is particularly critical. In order to ensure that castings do not leak during use and have good pressure retention capabilities, LVXUN has established a complete control process in multiple links such as design, manufacturing and testing.

(1) Preliminary design verification and simulation analysis

Before mold development, the technical team usually uses advanced flow and solidification simulation software to predict and analyze new products. This step helps to identify potential leakage risks such as shrinkage holes, pores, and weak closed areas.

(2) X-ray detection for internal defect control

To ensure that the internal structure of the casting is dense and free of major defects, X-ray imaging equipment will be used for inspection. Only castings that pass this test and meet the assessment standards can enter the subsequent airtightness test process.

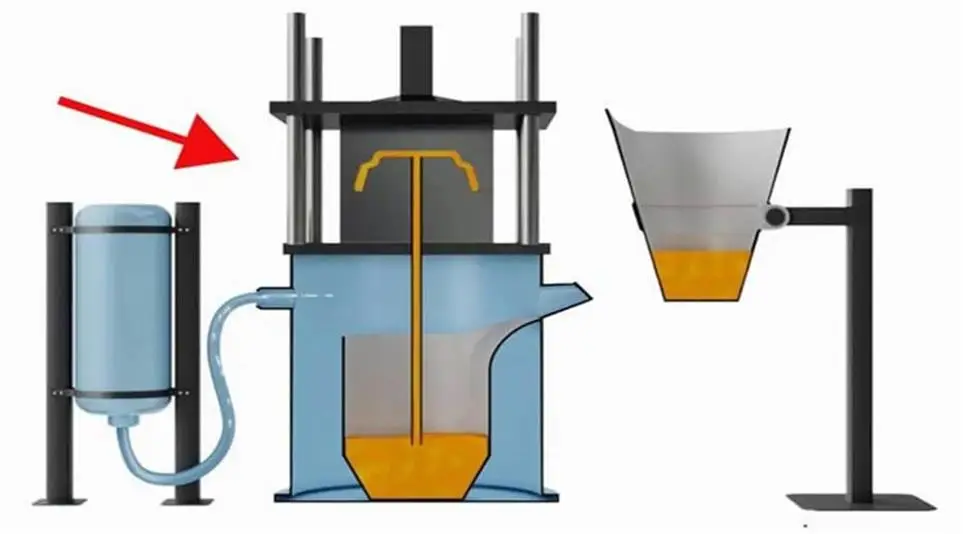

(3) Airtightness detection method

Before actually leaving the factory, a variety of detection methods will be used to verify the airtightness of aluminum castings:

Pressure decay method: Fill the casting with a certain pressure of gas and monitor the pressure change to determine whether there is a micro leak.

Mass flow method: measures the gas leakage flow rate under stable pressure, which is suitable for scenarios with clear leakage rate requirements.

Underwater bubble test: pressurize the casting and immerse it in water to observe whether bubbles are generated. This is one of the most intuitive leak detection methods.

(4) Chemical composition stability control

The airtightness of aluminum alloy is closely related to its organizational structure, and composition control is the basic guarantee. Direct reading spectrometer (OES) is usually used to analyze the purchased raw materials and each furnace of metal melt to ensure that the aluminum alloy composition is stable within the design range.

(5) Heat treatment process to improve organizational density

After standardized heat treatment, the microstructure of the casting will be more uniform and dense, thereby enhancing the overall mechanical properties and sealing performance. Especially for gravity cast aluminum parts, appropriate heat treatment can effectively eliminate internal stress and improve the consistency and reliability of airtight performance.

(6) Surface crack detection auxiliary process

In some occasions where airtightness requirements are extremely high, liquid penetration detection technology is also used to detect cracks on the surface of the casting. This method uses a penetrant to enter the micro cracks and then uses a developer to make them visible. It is an important means to identify subtle surface defects.

Summary

At LVXUN, we provide the above metal casting quality inspection methods to ensure that every part and component we manufacture meets our manufacturing standards and that our customers can also obtain the best quality castings and components in the industry.