Permanent Mold Casting | Comprehensive Metal Casting Guide

Among many metal forming processes, permanent mold casting stands out for its “reusable mold” feature. But the value of this technology is far more than just the life of the mold. It uses high-strength molds made of steel or cast iron to achieve efficient molding of molten metal under a variety of pouring methods such as gravity, low pressure or vacuum.

Compared with traditional sand casting, permanent mold casting has advantages in dimensional accuracy, surface quality and mechanical properties; compared with high-pressure die casting, it is more suitable for high-quality aluminum alloy castings under medium and low pressure conditions. From process stability to material properties, this method is becoming an ideal balance between precision manufacturing, processing costs and mass production. Please continue reading the following detailed introduction:

Table of Contents

1.What is permanent mold casting? How is it different from other casting processes?

Definition explanation

Permanent mold casting is a casting method that uses durable, reusable molds to make molten metal into parts and components. Unlike disposable sand casting, the molds used for permanent mold casting are usually made of steel or cast iron and can be used hundreds to thousands of times. This process usually uses gravity pouring, and low pressure or vacuum assistance can also be used to improve the filling effect.

Permanent mold casting vs sand casting

Sand casting is a expendable mold casting process, and permanent mold casting is a non-expendable mold casting mold casting process.

Compared with sand casting, the biggest advantage of permanent mold casting is that the reusable metal mold can bring higher dimensional accuracy, better surface quality and more stable mechanical properties. This is mainly due to the good thermal conductivity of the metal mold and the fast cooling rate, which can promote the molten metal to form a dense and fine grain structure and improve the comprehensive performance of the material.

Permanent mold casting vs die casting

In addition, permanent mold casting is more suitable for alloy casting under medium and low pressure conditions than die casting, especially for occasions requiring higher strength, better corrosion resistance and smaller processing allowance.

2.What materials are suitable for permanent mold casting?

Suitable metal materials

Permanent mold casting is suitable for processing metal materials with low melting point and good fluidity. The most common ones are aluminum alloys, such as A356, ADC12, A380, ZL101, ZL102, etc. Aluminum alloy is not only light in weight, but also has good thermal conductivity and corrosion resistance. It can also be quickly solidified in metal molds to obtain good density and surface quality. It is the most widely used material.

In addition to aluminum alloys, magnesium alloys are also very suitable for permanent mold casting, especially in areas where weight requirements are extremely sensitive, such as aerospace or high-end automotive industries. Copper alloys (such as brass and bronze) are also widely used in some industrial parts, especially those that require wear resistance and conductivity. In addition, some zinc alloys can also be used for permanent mold casting, but the frequency of use is low.

Unsuitable metal materials

It should be noted that permanent mold casting is not suitable for casting high-melting-point metals such as carbon steel, stainless steel and high-temperature alloys, because these materials will quickly cause mold thermal fatigue damage, reduce mold life, and require extremely high process control.

3.Permanent mold casting advantages and disadvantages

Advantages

The advantages of permanent mold casting are very significant, especially for the manufacture of metal parts with high requirements for precision, strength and repeatability. Its main advantages include:

The mold can be reused, which greatly saves the mold cost in long-term production and is suitable for medium and large batch production.

High dimensional accuracy, tolerance can be controlled within ±0.2mm, good consistency of parts, and small amount of subsequent machining.

Fast cooling speed, fine crystal structure, high strength of castings, and generally better mechanical properties than sand castings.

Good surface quality, conventional castings can reach Ra3.2~Ra6.3, without complex post-processing.

The mold can integrate cooling water channels, exhaust channels, core pulling devices, etc., with flexible structure and strong adaptability.

Disadvantages

Of course, this process also has certain limitations:

Large initial investment: long mold manufacturing cycle and high cost, not suitable for single piece or small batch customization.

Part shape is limited: metal molds are difficult to form complex inner cavities or deep hole structures, and the core pulling device has a complex structure and is easily damaged.

High requirements for operating process: mold preheating, pouring temperature, cooling control, coating spraying and other links must strictly follow the process specifications, otherwise it is easy to produce defects such as pores, cold shuts, shrinkage holes, etc.

Limited mold life: Although it can be reused, the mold still has a service life due to thermal fatigue, which is generally between 5,000 and 50,000 times, depending on the material and working conditions.

4.What are the types of permanent mold casting?

Permanent mold casting is a widely used process in metal processing. It relies on strong and reusable molds (usually made of cast iron, steel or graphite) to produce precision metal parts.

Depending on the way the molten metal enters the mold, this process can be divided into several types, including gravity permanent mold casting, slush permanent mold casting, low-pressure permanent mold casting and vacuum-assisted permanent mold casting.

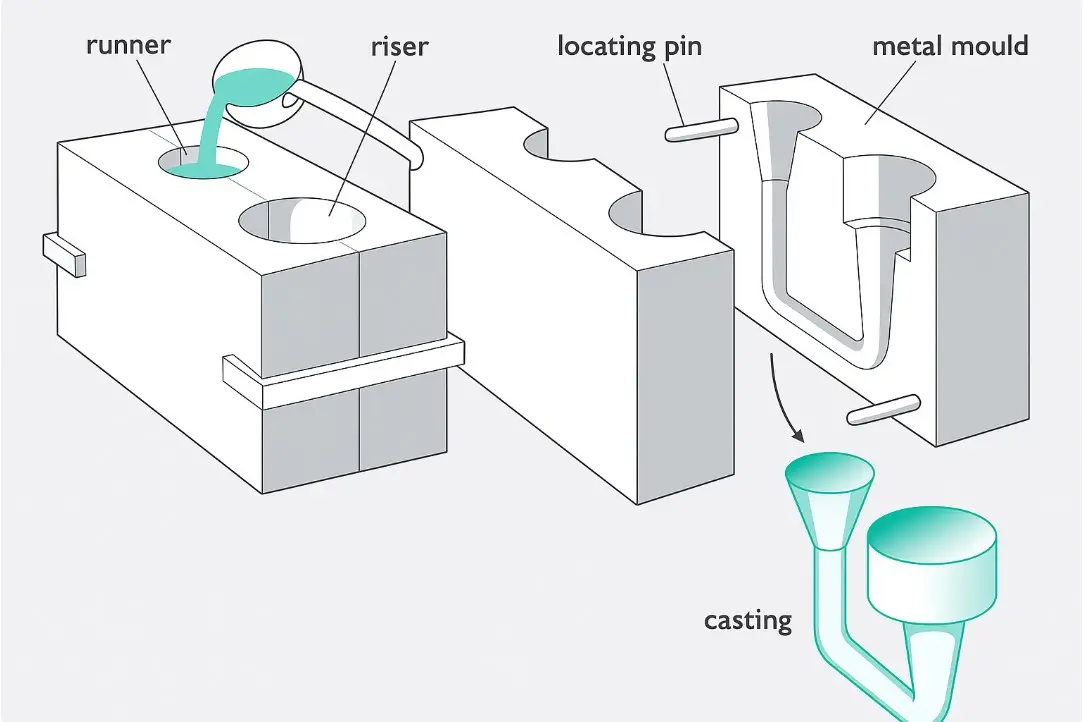

Gravity permanent mold casting

Gravity permanent mold casting is the most traditional and simplest method, also known as gravity casting. In this method, the molten metal enters the mold cavity by its own gravity, and the metal flow can be adjusted by vertical pouring or tilting the mold. The key to the process is to design a reasonable pouring system to ensure that the metal flows evenly in the mold.

This process is mainly used for non-ferrous metals such as aluminum, magnesium, and copper alloys. Compared with sand casting, it can provide better mechanical properties, smoother surfaces and lower porosity. For example, parts that require dimensional stability, such as automotive accessories, ship hardware and industrial machinery parts, are very suitable for production using gravity casting.

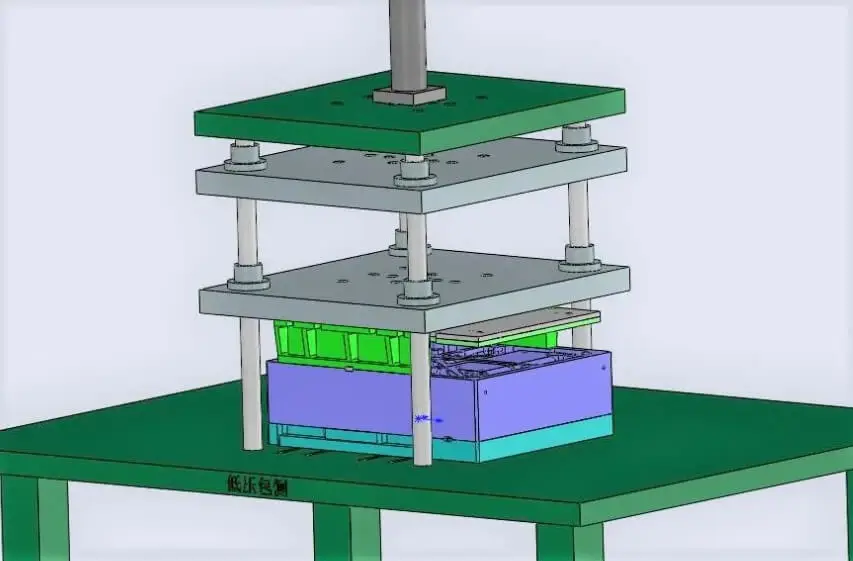

Low pressure permanent mold casting

Low pressure permanent mold casting is a more advanced technique that pushes molten metal upward into the mold cavity from below by applying low air pressure (usually between 3 and 15 psi) to a furnace or metal storage tank. Unlike gravity-based processes, this method allows for precise control of metal flow, reducing turbulence and ensuring uniform mold filling.

It is particularly suitable for the production of aluminum alloy castings, with advantages including high dimensional accuracy, few inclusions, low porosity and excellent mechanical properties. The process is widely used to manufacture demanding parts such as automotive wheels, cylinder heads and complex housings.

Slush permanent mold casting

Slush casting is a technique that specializes in the manufacture of hollow, lightweight, thin-walled castings. Compared with other methods, it is slightly weaker in dimensional accuracy and strength control, but it is effective in producing lightweight decorative metal products.

The process involves pouring molten metal into a heated metal mold, which begins to solidify from the mold wall. When the outer layer forms a metal shell of sufficient thickness, the unsolidified metal is quickly poured out to obtain a hollow structure.

This method is suitable for products such as lamp holders, statues, and toy models. It can provide consistent surface quality, but due to insufficient strength, the slush process is not suitable for load-bearing parts.

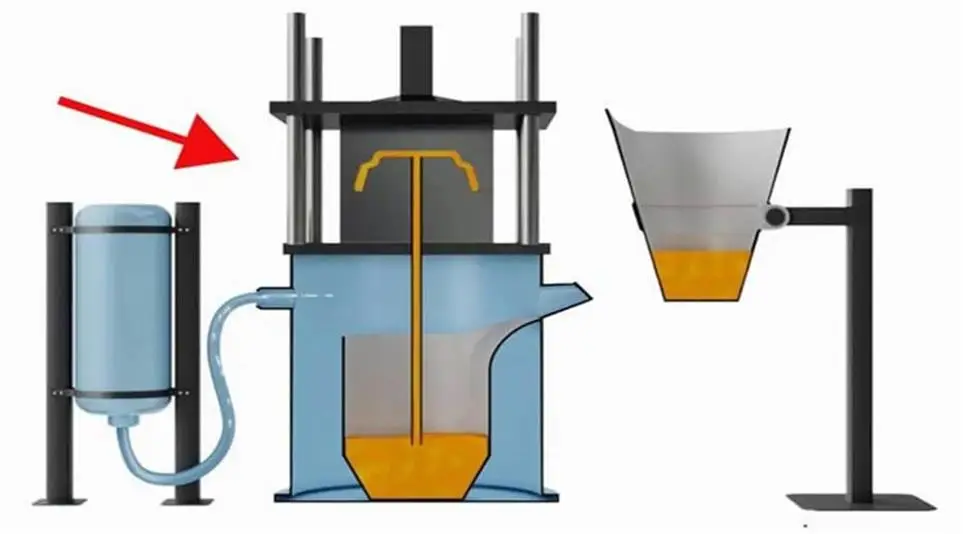

Vacuum permanent mold casting

Vacuum permanent mold casting is a high-precision technology that uses negative pressure to draw molten metal into the mold by forming a vacuum in the mold cavity. This not only reduces gas entrapment and porosity defects, but also significantly improves the mechanical strength and density of the casting.

This method is very suitable for manufacturing thin-walled, complex-shaped parts with high dimensional accuracy requirements.

Aerospace, medical equipment and automotive manufacturing, which are fields with strict requirements for parts, have a strong demand for vacuum castings.

In summary:

Gravity casting: The most basic process, the lowest cost, suitable for medium and high-volume products with simpler dimensions.

Slush casting: Specially used for lightweight hollow decorative parts, with high material utilization, but insufficient part strength.

Low-pressure casting: Control the mold entry through air pressure to improve density and performance, suitable for complex structures and thin-walled parts.

Vacuum casting: Minimum air inclusions, high purity, best performance, suitable for precision high-performance parts.

These four technologies are typical types of permanent mold casting, each of which differs in filling method, casting quality, applicable metals (mostly aluminum, magnesium, copper alloys) and application areas. When choosing, a comprehensive evaluation should be made based on part complexity, dimensional accuracy, material performance requirements and production costs.

5.Detailed analysis of the complete process of permanent mold casting

In the permanent mold casting process, first of all, the accuracy of the mold directly determines whether the final product can meet the required tolerance requirements. Secondly, in order to ensure that the casting meets the established design standards and dimensional accuracy, the entire process must be strictly carried out in accordance with the established steps, and careful monitoring and adjustment must be carried out in each link. Finally, in industrial manufacturing, we at LVXUN are well aware that high-standard control of the process is the key to ensuring the quality of metal parts, meeting customer technical requirements, and adapting to specific application scenarios.

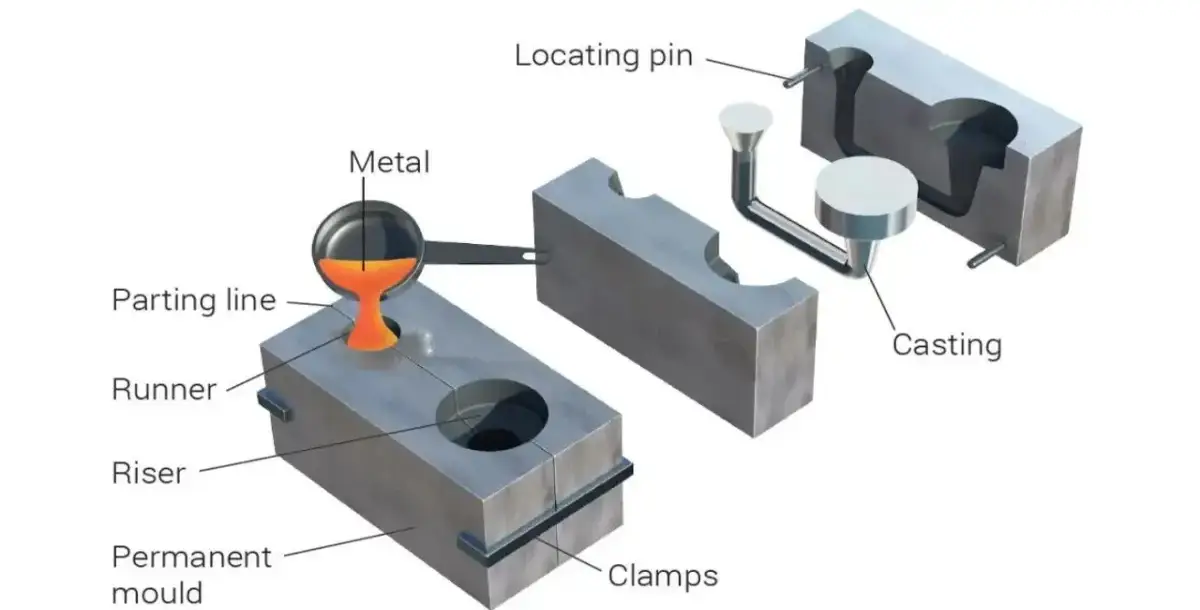

Mold manufacturing

Before casting, the first thing to do is to design and manufacture the mold. Usually, the mold is made of tool steel, gray cast iron, and graphite. The basis for material selection is whether it can maintain good thermal stability and mechanical strength during repeated use at high temperatures.

The mold is usually composed of two halves or multiple sections, which can be combined with cores, inserts, vents and cooling systems to achieve more complex geometric structures, cavities and thinner wall thickness molding requirements.

Modern foundries widely use 3D CAD modeling and CAE simulation software in the mold development stage to predict metal flow paths, thermal field distribution and potential defects, and optimize mold structure, gate system and venting layout accordingly to improve the yield rate from the source.

Heating the mold

Before putting it into production, the mold needs to be fully preheated to avoid sudden solidification, cold shut or erosion when the molten metal enters the cold mold, and it can also reduce the risk of mold cracking caused by thermal shock. The preheating temperature is usually set according to the thermal properties of the selected alloy, ranging from 150°C to 300°C. The mold surface also needs to be coated with a special high-temperature resistant coating, such as a graphite-based or ceramic-based release agent, to play a role in heat insulation, protection and smooth demolding of the casting.

Metal material selection

Non-ferrous metals with low melting points and good fluidity are usually selected, such as aluminum alloys, magnesium alloys, copper alloys and zinc alloys. Aluminum alloys are particularly suitable for lightweight automobiles and aviation parts manufacturing due to their excellent strength-to-weight ratio and good casting properties. According to the purpose and performance requirements of the casting, the alloy grade and process parameters, such as melting temperature, mold temperature, pouring time and cooling method, must be accurately matched to ensure that the cast parts have good mechanical properties, density and machinability.

Pouring molten metal

Pouring is one of the key links in the entire casting process. Permanent mold casting can be cast in a variety of ways, such as gravity casting, tilting casting, low-pressure filling or vacuum-assisted casting. Traditional gravity casting is suitable for parts with relatively simple structures. It is easy to operate but has limited fluidity and filling capacity. Tilt or reverse tilt casting technology can control the metal filling rate, reduce turbulence, and reduce the risk of inclusions and pores.

In situations where the internal quality of the casting is extremely high, such as in the production of aerospace or medical device components, vacuum-assisted casting technology is often used to remove air from the mold cavity by applying negative pressure. The purpose of this is to improve the density and integrity of the casting.

Cooling and solidification

The metal material of the permanent mold has high thermal conductivity, which can achieve faster cooling, help to form fine and uniform grains, and improve the strength and toughness of the part. For more sophisticated thermal management, the mold often has built-in cooling water channels or uses external air cooling devices. The critical design of the cooling system not only affects the cycle efficiency, but also affects the repeatability of the product and the cost of mold maintenance. By carefully designing a cooling strategy that matches the alloy and part structure, manufacturers can improve casting quality, reduce scrap, and extend the life of expensive permanent molds.

Part removal and ejection

When the casting is solidified, the casting is smoothly removed from the mold cavity using the ejection system built into the mold. The system includes ejector pins, push plates, hydraulic ejection, etc., which ensure the integrity of the part while maintaining the repeatability and efficiency of the mold structure. To prevent the casting from cracking or sticking during demolding, the appropriate draft angle and surface treatment should be considered during design. LVXUN casting usually uses modern casting equipment, which is equipped with an automated ejection system to further improve production efficiency and reduce the uncertainty caused by manual intervention.

6.What types of parts or industries are permanent mold casting suitable for?

Permanent mold casting is widely used in industrial parts with high requirements for structural strength, precision and dimensional consistency, and with medium or above production batches. The following are several typical industries and application examples:

Automotive industry:

Such as engine block, cylinder head, water pump housing, gearbox housing, oil pan, suspension bracket, brake bracket, etc. These parts usually have functions such as pressure bearing, heat dissipation, and shock absorption, and require high structural strength and good dimensional accuracy. Permanent mold casting just meets these requirements.

Aerospace:

Such as seat connectors, support frames, fuel distribution pipes, etc., these parts have extremely high requirements for the balance of weight and strength, and the lightweight and high-strength characteristics of aluminum alloys are fully reflected through permanent mold casting.

Electrical equipment and household appliances:

Such as motor housings, compressor end covers, heat sinks, electronic equipment housings, etc., which have high requirements for heat dissipation, corrosion resistance and appearance.

Hydraulic and industrial machinery:

Such as pressure-bearing components such as valve bodies, gear boxes, and control housings, which are widely used in engineering machinery, agricultural machinery and industrial automation equipment.

7.Permanent Mold Casting vs Die Casting: What is the difference between these two processes?

Although both permanent mold casting and die casting use metal molds, there are significant differences between the two in terms of process nature, part performance and application areas:

Different pouring methods:

Permanent mold casting uses natural gravity or low-pressure filling, and the filling speed is slow, which is suitable for parts with uniform structure and small internal stress; while die casting uses high pressure and high speed to press molten metal into the mold cavity, which can manufacture complex thin-walled structures, but it is easy to produce pores and stress accumulation.

Differences in mold structure:

The die-casting mold design is more complex and needs to withstand high-pressure impact. It often has multiple core pulling mechanisms, cooling water circuits and exhaust systems; while the permanent mold mold structure is relatively simple and suitable for parts of medium complexity.

Casting performance:

Permanent mold castings usually have fine grains, few pores, are suitable for subsequent heat treatment, and have excellent mechanical properties; while die castings are prone to pores due to high-speed filling, are not suitable for heat treatment such as T6, and have slightly inferior strength.

Surface quality and efficiency:

Die casting has very good surface quality and high production efficiency, which is suitable for products with an annual output of more than hundreds of thousands of pieces; permanent mold casting has lower efficiency, but is more suitable for parts that pursue structural strength and comprehensive performance.

8.Summary

Through comprehensive analysis and introduction, we can draw a conclusion that permanent mold casting is a cost-effective solution between sand casting and die casting, especially suitable for medium-volume, high-demand, and medium-complex industrial metal parts.

LVXUN’s casting capabilities

In the field of metal casting, LVXUN has always provided customers with reliable solutions based on stable process control and rich practical experience. We have advanced casting production lines, high-precision processing equipment and a professional engineering and technical team, which can flexibly respond to various customized needs of parts with complex structures and high precision requirements.

Moreover, from casting to CNC machining and subsequent surface treatment, we provide customers with one-stop service to ensure that every link is accurate and efficient, and maximize the consistency and delivery efficiency of products.

With a deep understanding of material properties and strict control of process details, LVXUN can not only meet the delivery and quality requirements of mass production, but also achieve a good balance in product performance, appearance and cost control. Our customers cover multiple industries and have won wide recognition and long-term cooperation.

Choosing LVXUN means choosing a casting partner with solid technology, fast response and trustworthiness. We look forward to exploring efficient and high-quality manufacturing solutions with you.

FAQs:

What is the opposite casting process to permanent mold casting?

The opposite of permanent mold casting is the process using disposable molds, such as sand casting, investment casting, lost foam casting, etc. The characteristic of these processes is that the mold needs to be remade after each pouring, which is suitable for small batches or parts with complex shapes.

Is high pressure die casting a type of permanent mold casting?

Strictly speaking, high pressure die casting and permanent mold casting are related, but the industry usually does not directly classify high pressure die casting as a subcategory of permanent mold casting.

The reason is:

1.Both use metal molds, and the molds can be reused, which is their commonality.

2.But permanent mold casting usually refers to gravity casting or low-pressure casting, and the molten metal fills the mold cavity by gravity or lower pressure.

3.High pressure die casting uses high pressure and high speed filling, and the process characteristics, equipment, mold structure requirements and part characteristics are very different from traditional permanent mold casting.

Therefore, in academic and industrial definitions, die casting is regarded as another independent metal mold casting process. It belongs to the same category as permanent mold casting, but it is not strictly “permanent mold casting”.

Which aluminum alloys, magnesium alloys or copper alloys are more suitable for different types of permanent mold casting?

Different alloys have different sensitivities to fluidity, hot cracking tendency, and filling methods. Aluminum-silicon alloys with good fluidity are suitable for gravity casting; magnesium alloys that are sensitive to pores are suitable for low-pressure or vacuum casting; high thermal conductivity copper alloys often require specially designed cooling channels.

Can permanent mold casting be used for hollow, thin-walled or large parts? Are there any applicable restrictions for different types?

Slush casting is suitable for hollow decorative parts; low-pressure casting and vacuum casting are suitable for thin-walled and dense parts; large parts require special mold reinforcement and heating systems.

Is permanent mold casting the same as tiltable casting? Is it a separate type?

Tiltable pouring is a special method of permanent mold casting. It controls the metal filling speed by tilting the mold, reduces turbulence and oxidation, and is an improved type of gravity casting.

What is the relationship between permanent mold casting and metal mold casting, die casting, and semi-solid casting?

Both permanent mold casting and die casting belong to metal mold casting, but die casting is high-pressure filling, and semi-solid casting is a filling method in the state of metal slurry. The scope of permanent mold casting is relatively narrow, generally referring to metal mold pouring under low pressure or gravity.

What are the differences in production batches suitable for different types of permanent mold casting?

Gravity casting has the lowest mold cost and is suitable for medium batches; low-pressure casting and vacuum casting are more expensive and more suitable for large batches of high-quality parts.

What do you think?

[…] Mold design is the basis of copper mold casting, and its rationality directly affects the formation and quality of metallic glass. Copper molds are usually made of copper alloys with high thermal conductivity, which can quickly cool the melt and promote the formation of amorphous structure. The design of the mold needs to consider the following aspects: […]

Comments are closed.