High Precision Aluminum Prototype Manufacturing

In modern manufacturing, aluminum prototyping has become an indispensable part of the product development process. It not only helps designers verify structure and function but also identifies potential problems before production, saving significant time and costs. With its excellent mechanical properties, good machinability, and aesthetically pleasing surface texture, aluminum is increasingly becoming the preferred material for prototyping.

Table of Contents

1.What is a Product Prototype?

A product prototype is used in the product development process to transform a design from a digital or conceptual form into a tangible, verifiable physical sample. This sample is used to test and verify key aspects of the product, such as appearance, assembly, and function, identifying and correcting design or manufacturing problems before mass production.

Specifically, its key points include:

It is a physical entity, not just drawings or 3D renderings.

It is not necessarily the final product, but it has a high degree of similarity to the final product in function, structure, or appearance.

The purpose of manufacturing is to verify the feasibility, assemblability, functionality, and manufacturing processes of the design, rather than for immediate mass production.

It allows for feedback through trial production before mold making and mass production, thereby reducing risk and saving costs.

2. Advantages of Aluminum as a Prototype Material

Superior Mechanical and Functional Properties

Aluminum and its alloys combine lightweight with high strength, enabling them to withstand significant loads and deformations while maintaining structural stability. They not only accurately reflect the actual performance of metallic products but are also suitable for assembly, stress, and functional testing, making them ideal materials for high-reliability prototypes.

Excellent Machinability and Precision

Aluminum is easy to cut, mill, and form. Whether using CNC machining, casting, or 3D printing, high dimensional accuracy and smooth surfaces can be achieved. Its minimal machining errors ensure a tight prototype structure and smooth assembly, laying the foundation for subsequent mass production.

Good Heat Resistance and Thermal Conductivity

Aluminum possesses excellent thermal conductivity and high-temperature resistance, maintaining deformation stability in high-temperature or extreme environments. For products requiring heat dissipation or thermal performance testing (such as electronic device housings and heat sinks), aluminum prototypes provide more realistic and reliable verification results.

Corrosion Resistance and Beautiful Appearance

The naturally formed oxide layer on the aluminum surface effectively prevents atmospheric and chemical corrosion, ensuring the prototype remains stable and durable in humid or complex environments. Meanwhile, aluminum’s texture and metallic luster give prototypes an excellent appearance, which can be further enhanced through processes such as anodizing and sandblasting.

A Cost-Effective Choice

Although slightly more expensive than some plastics, aluminum prototypes offer advantages in durability, processing efficiency, and reusability. High strength and low wear mean less rework and replacements, resulting in a more cost-effective overall product and shorter development cycles.

3.Aluminum Alloys Suitable for Prototyping

When selecting aluminum alloys for product prototyping, ease of processing, structural strength, corrosion resistance, and cost must be considered. Below are some common aluminum alloys used in prototyping and their suitable applications:

3003 Aluminum Alloy

This is a non-heat-treatable manganese alloy with approximately 20% higher strength than pure aluminum, while maintaining excellent ductility and malleability. It is easy to stamp, bend, and weld, making it suitable for prototypes with low load requirements but complex structures or delicate appearances, such as storage tanks, shells, and appliance panels.

5052 Aluminum Alloy

5052 aluminum alloy, with magnesium as its main alloying element, possesses excellent resistance to water and chemical corrosion, along with high strength and toughness. It is particularly suitable for prototypes used in humid, salt spray, or chemical environments, such as ship parts, liquid containers, and experimental equipment, making it an ideal choice for environmentally resistant prototypes.

6061 Aluminum Alloy

This is one of the most commonly used aluminum alloys in prototyping. It is heat-treatable and combines high tensile strength, excellent corrosion resistance, and outstanding machinability. 6061 is machinable and suitable for CNC machining or 3D printing, often used to create structurally and functionally demanding prototypes, such as mechanical components, electronic housings, and automotive parts.

7075 Aluminum Alloy

7075 is a high-strength, heat-treatable aluminum alloy, with zinc as its main alloying element. Its strength and hardness are far superior to ordinary aluminum. Lightweight yet rigid, it is ideal for prototypes with extremely high requirements for load-bearing capacity, precision, and structural strength, such as aerospace components, motion equipment, and engineering structures.

6063 Aluminum Alloy

6063 is mainly composed of magnesium and silicon, possessing good formability, surface finish, and corrosion resistance. Although its strength is lower than 6061, it has a superior appearance, making it suitable for prototypes used for aesthetic display or lightweight structures, such as frames, decorative parts, and architectural models.

The following table presents this commonly used aluminum alloy:

| Aluminum Alloy Grade | Main Components | Heat – Treatable | Main Features | Common Applications |

| 3003 | Aluminum + Manganese | No | Strength ~20% higher than pure aluminum, good ductility | Cookware, liquid storage tanks, light – duty equipment |

| 5052 | Aluminum + Magnesium | No | High strength, strong corrosion resistance, suitable for marine environments | Marine parts, fuel tanks, anti – corrosion equipment |

| 6061 | Aluminum + Magnesium + Silicon + Chromium + Copper | Yes | High mechanical strength, good corrosion resistance, versatile | Automotive structural parts, electronic device enclosures |

| 7075 | Aluminum + Zinc + Copper + Manganese | Yes | Lightweight and high strength, excellent performance | Aircraft structural parts, high – load aerospace components |

| 6063 | Aluminum + Silicon + Magnesium | Yes | Good extrusion performance, attractive surface, medium strength | Architectural profiles, window frames, pipes, furniture |

4.What are the methods for making aluminum prototypes?

There are various methods for manufacturing aluminum prototypes. Common processes include CNC machining, sheet metal forming, aluminum extrusion, die casting, electrical discharge machining, and metal 3D printing. Different methods are suitable for different structures, performance, and quantity requirements. The following is an introduction and analysis of several mainstream processes:

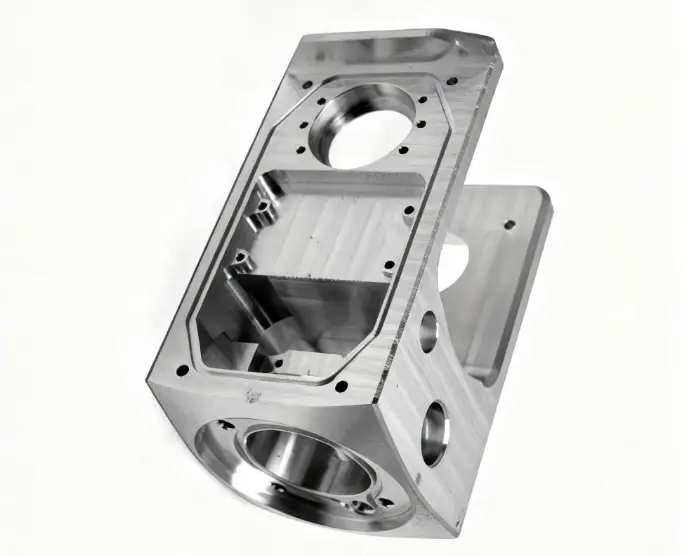

(1) CNC Machining

Process Principle:

By using computer-controlled cutting tools to cut aluminum blanks in a multi-axis coordinate system, excess material is gradually removed to obtain high-precision three-dimensional parts. Common forms include CNC milling, turning, and engraving.

Advantages:

High precision, achieving tolerances of ±0.01mm or even higher.

Smooth surface finish, no molds required, suitable for rapid iterative design.

Compatible with various aluminum alloys, such as 6061 and 7075, with stable mechanical properties.

Disadvantages:

Low material utilization rate, belonging to subtractive manufacturing.

Not suitable for mass production, high unit cost.

Applicable scenarios:

Suitable for functional prototypes, assembly verification parts, and high-precision structural samples; the most mainstream process for making aluminum prototypes.

(2) Sheet metal forming

Process principle:

Aluminum sheets are processed into structural parts or shell prototypes through cutting, stamping, bending, and welding.

Advantages:

Fast processing speed, suitable for planar and thin-walled structures.

Good part consistency, suitable for mass production.

Low cost, suitable for shell or frame-type prototypes.

Disadvantages:

Not friendly to complex curved surfaces and thick-walled structures.

Welded strength is slightly lower than that of a solid aluminum part.

Applicable Scenarios:

Widely used for prototype structural components such as electronic device housings, industrial control boxes, and mechanical panels.

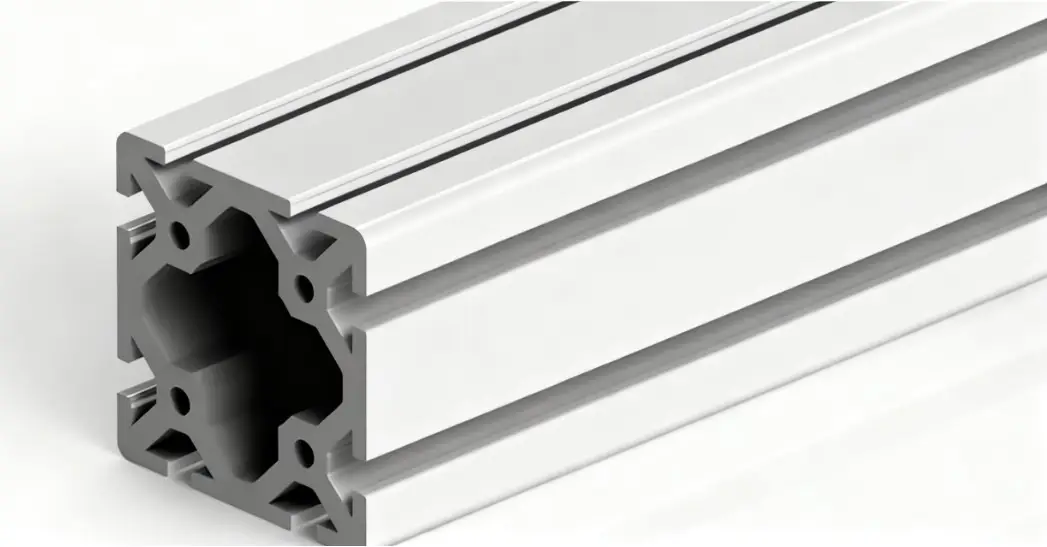

(3) Aluminum Extrusion

Process Principle:

Heated aluminum alloy is extruded through a die to form long strip-shaped parts with a fixed cross-section, such as brackets, guide rails, or frames.

Advantages:

High forming efficiency and good cross-sectional consistency.

Less material waste, enabling lightweight structures.

Smooth surface, allowing for direct anodizing.

Disadvantages:

Only suitable for parts with a constant cross-section.

High die cost and long production cycle.

Applicable Scenarios:

Suitable for producing prototype parts with regular shapes such as structural supports, guide rails, heat sinks, and outer frames.

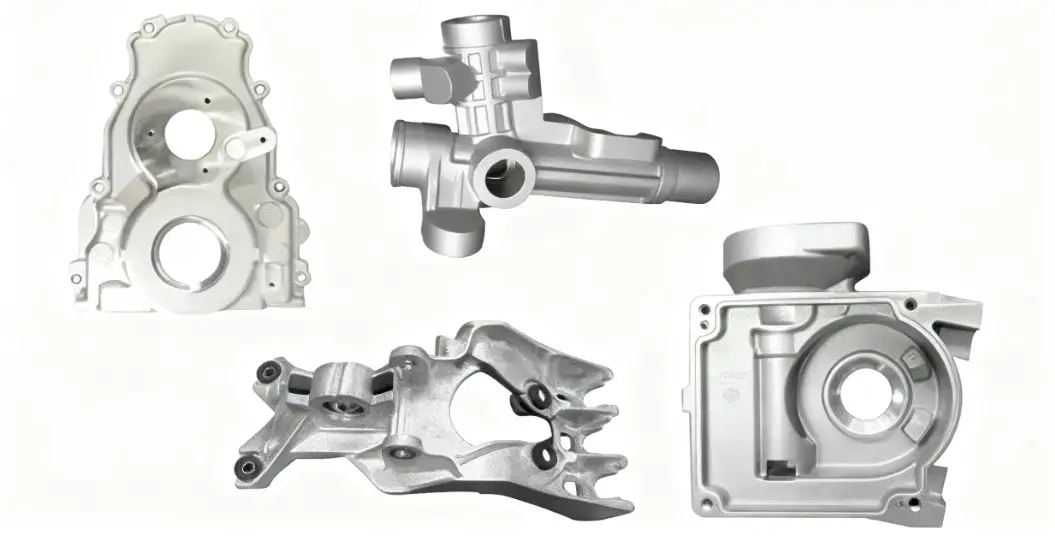

(4) Die Casting

Process Principle:

Liquid aluminum is pressed at high speed into a steel mold and cooled and solidified under pressure.

Advantages:

Die cast aluminum can be used to manufacture parts with complex structures and fine surface details.

High dimensional accuracy and mechanical properties close to mass-produced parts. Suitable for small to medium batch prototypes or functional verification stages.

Disadvantages:

High mold cost and long production cycle.

Not suitable for frequent design modifications.

Applicable scenarios:

Commonly used for structural component prototypes in the automotive, aerospace, or electronics fields, especially when verifying casting performance.

(5) Electrical Discharge Machining

Process Principle:

Utilizes the high temperature generated by electrical discharge to melt or vaporize aluminum surface materials, thereby achieving fine machining. Commonly used for machining complex internal holes, sharp angles, or hard structures.

Advantages:

Can machine complex geometries that are difficult to complete with traditional cutting.

High machining accuracy, suitable for microstructures and deep cavity details.

Disadvantages:

Slow machining speed and low efficiency.

Surface may require subsequent grinding or polishing.

Applicable scenarios:

Suitable for complex mold cavities or precision prototypes with extremely high structural feature requirements.

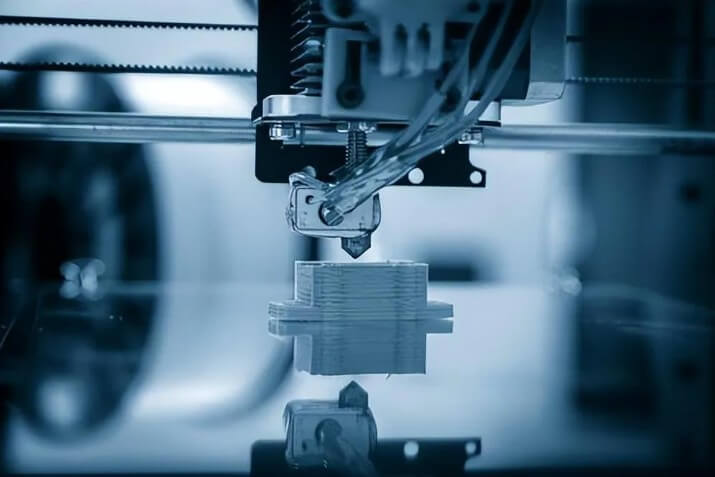

(6) Metal 3D Printing

Process Principle:

Uses laser to melt aluminum alloy powder (such as AlSi10Mg) layer by layer to construct a three-dimensional structure. This is a typical additive manufacturing process.

Advantages:

Enables complex internal structures and lightweight designs.

No molds required, suitable for rapid iteration and small-batch customization.

High material utilization and minimal waste.

Disadvantages:

Slower printing speed and higher cost per unit.

Higher surface roughness, requiring post-processing.

Applicable scenarios:

Best suited for manufacturing prototypes with complex structures, numerous internal channels, or optimized topologies, such as aerospace parts and heat dissipation modules.

Summary and Selection Recommendations

High-precision, functional prototypes: CNC machining is preferred.

Complex geometry and internal structures: Metal 3D printing is recommended.

Small to medium batch production, near-mass production performance: Die casting is suitable.

Lightweight frames and shells: Sheet metal forming or aluminum extrusion can be used.

Intricate details or deep cavity structures: Electrical Discharge Machining (EDM) is recommended.

5.How to make metal prototypes?

At LVXUN, we typically create aluminum prototypes, following these 7 steps: from objectives and material selection to process, post-processing, and verification.

Step 1 — Define Objectives

Before starting any machining, clearly define: Is this prototype for visual demonstration, assembly verification, or functional load testing? The budget, quantity, delivery date, and whether it needs to be consistent with mass production materials must also be determined. Objectives determine everything—different objectives require different processes.

Step 2 — Design and Preparation (CAD + DFM)

Use 3D CAD to model and perform manufacturability (DFM) checks: Mark key mating surfaces, tolerances, minimum wall thickness, remove unnecessary sharp corners, and reserve clamping surfaces and fixture locations.

Step 3 — Select Materials (Common Aluminum Alloys)

If consistency with mass production is required, use the same alloy directly (e.g., 6061/7075/5052, etc.); if only visual demonstration or assembly is needed, easily machinable 6061 or 3003 can be selected. Material selection is influenced by strength, corrosion resistance, and thermal conductivity requirements.

Step 4 — Selecting Mainstream Processes (6 types) as Needed

Multiple processes are commonly used to create metal prototypes. The specific choice depends on design complexity, budget, and performance requirements. Common methods include CNC machining, sheet metal forming, aluminum extrusion, die casting, EDM, and metal 3D printing. Detailed information is available in paragraph four, “Methods for Creating Aluminum Prototypes,” which can be scrolled up if needed.

Step 5 — Process Combinations and Testing Strategies

A common and practical approach is to first create a functional prototype using CNC machining to verify dimensions and assembly. Then, if necessary, 3D printing can be used to verify complex structures. Finally, if mass production simulation is required, small batch die casting or trial production using aluminum molds can be performed. This controls costs and allows for the identification of design issues at each step.

Step 6 — Post-processing

Select based on functional requirements: anodizing (improves corrosion resistance and color), mechanical polishing, sandblasting (improves feel and appearance), heat treatment (improves strength), or electroplating (for special conductivity and decorative requirements). 3D printing or casting typically requires support removal, heat treatment, and machining of critical mating surfaces.

Step 7 — Testing and Iteration

Perform targeted tests such as strength, assembly, thermal cycling, and surface corrosion resistance. Record the reasons for failures and return to CAD for localized corrections before proceeding to the next prototype. Rapid iteration in the prototyping stage can significantly reduce subsequent mass production risks and costs.

6.Applications of Aluminum Prototypes

Automotive Industry:

Used for design verification of body structural components, engine parts, and battery housings, helping to test strength, heat dissipation, and assembly accuracy, especially suitable for lightweight requirements.

Aerospace:

Used for early testing of fuselage frames, support components, and internal structures, verifying lightweight, high-strength designs to ensure safety and performance.

Consumer Electronics:

Prototyping of mobile phone, laptop, and wearable device casings to test appearance, heat dissipation performance, and assembly accuracy.

Medical Devices:

Prototyping of casings, supports, and instrument components to ensure accuracy, corrosion resistance, and surface finish.

Industrial Automation & Robotics:

Prototype verification for fixtures, supports, and moving parts, ensuring structural strength and motion accuracy while reducing load.

New Energy & Power Equipment:

Prototype fabrication of battery trays, heat dissipation components, and supports to test heat dissipation and structural stability in advance.

Home Appliances, Lighting & Furniture:

Appearance samples and assembly testing; aluminum surface treatments give prototypes a near-finished look.

7.LVXUN Helps You with Aluminum Prototyping

Whether you need to validate design concepts, test functional performance, or prepare for mass production, LVXUN provides comprehensive aluminum prototyping services. Equipped with advanced manufacturing equipment and precision testing instruments, and with an experienced technical engineering team familiar with various mainstream processes such as CNC machining, die casting, aluminum extrusion, sheet metal forming, and 3D printing, we can flexibly choose the most suitable solution according to your project needs.

From rapid prototyping to small-batch trial production, we consistently ensure precision and consistent quality in every detail through strict process standards and efficient project management. Choosing LVXUN means you’ll not only get high-quality aluminum prototypes, but also entrust subsequent mass production to a professional team, truly achieving an integrated service from prototyping to mass production. Simply upload your files to start a new project!

8.Summary:

Aluminum prototypes are a crucial link between design and mass production in manufacturing. With their excellent performance and processing flexibility, they efficiently validate designs and optimize product structures. Choosing the right aluminum alloy and process not only improves prototype quality but also lays a solid foundation for mass production.

FAQs:

Why make aluminum prototypes?

Aluminum prototypes can verify the product’s structure, dimensions, strength, and assembly before mass production, helping to identify design problems and reduce later modification costs.

Which aluminum alloy is best for prototyping?

6061 aluminum alloy is the most common choice due to its high strength, good machinability, and corrosion resistance. For higher strength, 7075 can be selected, while 5052 is suitable for high corrosion resistance requirements.

How much does it cost to make an aluminum prototype?

The cost depends on the process type, part complexity, precision, and quantity. The price of a single CNC prototype typically ranges from several hundred to several thousand US dollars.

What should be considered when making aluminum prototypes?

Avoid designing excessively thin structures, set appropriate tolerances, and ensure tooling accessibility; confirm material and tolerance requirements with the machining supplier before placing an order.

Can aluminum prototypes be used directly for mass production?

If the same alloy and processes as mass production (such as die casting or CNC) are used, a smooth transition to small-batch production is possible; otherwise, process parameters need to be readjusted.

Where can I find reliable aluminum prototype manufacturers?

Recommendations can be found through manufacturing platforms, machining service provider websites, or professional communities. When choosing a manufacturer, pay attention to equipment capabilities, delivery time, case experience, and after-sales service.