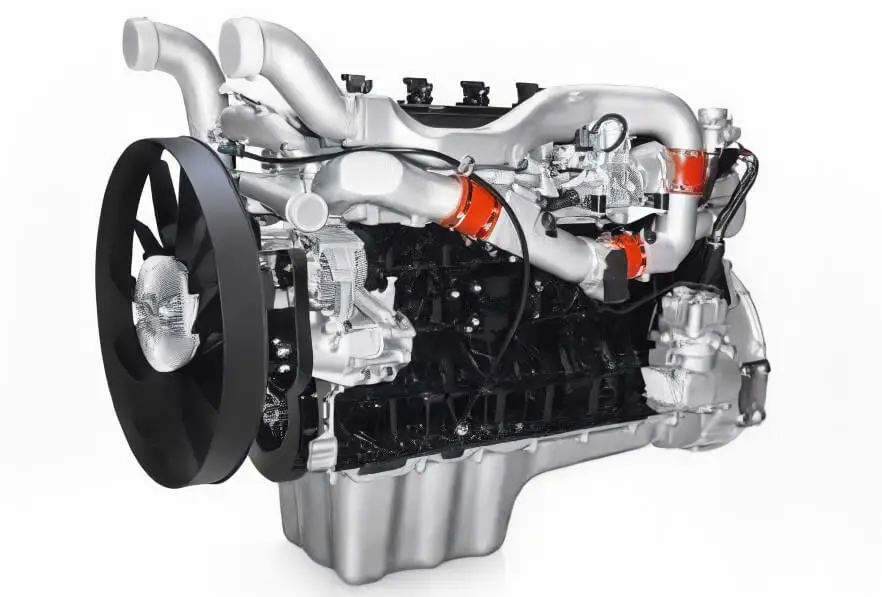

Cast Iron Engine Block: The Hardcore Strength of Traditional Materials

When it comes to engines, power, displacement, or turbocharging are likely the first things that come to mind. However, the core that truly underpins these performance features lies in the engine block. Cast iron engine blocks, in particular, have held a prominent place in the automotive industry for decades, thanks to their durability, pressure resistance, and heat resistance. Even with the increasing prevalence of lightweight aluminum alloy blocks, cast iron engine blocks remain a popular choice among manufacturers and enthusiasts for their reliability and potential for modification.

Table of Contents

1.What is an Engine Block?

The engine block is one of the most core components of an internal combustion engine, often referred to as the “body” of the engine. It mounts and supports components such as the cylinder, piston, and crankshaft, enabling them to operate properly under high temperatures and pressures. Cylinder blocks are typically constructed of cast iron or aluminum alloy, ensuring both strength and rigidity while also facilitating heat dissipation.

In addition, the engine block is equipped with a coolant jacket and oil channels, which provide sealing, lubrication, and heat dissipation, ensuring stable combustion chamber pressure. The cylinder block is both the backbone of the engine and the core of the entire powertrain.

2.The Evolution of the Engine Block

The evolution of the engine block is essentially a process of continuous trade-offs and optimizations in the automotive industry between performance, weight, and manufacturing processes.

In the early days, engine blocks were almost exclusively made of gray cast iron. This material offers high strength, good wear resistance, and good workability, enabling it to withstand the relatively modest power and pressure demands of internal combustion engines at the time. While cast iron engine blocks offer advantages such as durability and longevity, they also have significant disadvantages: their weight leads to high fuel consumption and hinders improved power response.

As engine performance continued to improve, especially in the mid-to-late 20th century, automakers began experimenting with aluminum alloy cylinder blocks. Aluminum is approximately 40% lighter than cast iron, significantly reducing overall weight while also offering improved heat dissipation, making it ideal for high-speed, high-compression ratio engines. However, aluminum’s strength and wear resistance are inferior to cast iron, so engineers addressed the wear issue by inserting cast iron sleeves in key locations or using high-silicon aluminum alloys.

In modern times, cylinder block materials and designs have further evolved. On the one hand, aluminum alloys have become the mainstream choice for most passenger car engines; on the other hand, some high-performance or commercial engines still rely on cast iron or high-strength alloys for ultimate durability. At the same time, cylinder block design is becoming increasingly sophisticated, with optimization of wall thickness, hollow structures, and other methods employed to reduce weight while maintaining strength.

Cast Iron vs Aluminum Alloy Performance Comparison (Typical Range)

| Property Indicator | Cast Iron (Gray Cast Iron/Ductile Iron) | Aluminum Alloy (Al-Si Series for Engine Applications) |

| Density | 6.8 – 7.3 g/cm³ | 2.65 – 2.8 g/cm³ |

| Tensile Strength | 200 – 400 MPa (Gray Cast Iron)400 – 800 MPa (Ductile Iron) | 150 – 400 MPa (Common Die-Casting/Casting Aluminum Alloys) |

| Yield Strength | 130 – 350 MPa (Depends on Type) | 80 – 250 MPa |

| Hardness | 180 – 300 HB (Gray Cast Iron)≥300 HB (Special Grades of Ductile Iron) | 60 – 120 HB |

| Young’s Modulus | 110 – 170 GPa | 65 – 80 GPa |

| Thermal Conductivity | 35 – 60 W/m·K | 120 – 180 W/m·K |

| Coefficient of Thermal Expansion (CTE) | 10 – 12 ×10⁻⁶ /K | 22 – 25 ×10⁻⁶ /K |

| Wear Resistance | High (Especially for Ductile Iron) | Low (Requires Cylinder Liners or Surface Treatment) |

| Corrosion Resistance | Poor, Requires Rust Prevention/Coolant Protection | Good, but Prone to Pitting Corrosion, Requires Protection |

3.Why is Cast Iron Used for Engine Blocks?

The reason is simple: when strength and durability are more important than lightweight, cast iron is particularly well-suited. This is especially true for heavy-duty diesel engines, which must withstand high temperatures, high pressures, and prolonged high loads. Cast iron is an ideal choice. The following are the advantages of cast iron engine blocks:

● Cast iron is not only readily available and relatively inexpensive, but also offers exceptional strength and durability.

● Cast iron engine blocks can withstand high operating temperatures and pressures, and you can drill large-diameter holes in them to accommodate larger pistons, boosting engine power.

● Furthermore, cast iron has excellent thermal conductivity, which helps dissipate heat during engine operation.

● It also offers excellent vibration damping properties, reducing vibration and noise during engine operation, ensuring a smoother and more reliable engine.

● Furthermore, cast iron is relatively mature in processing and maintenance, making subsequent lining and repair relatively easy, making cast iron engine blocks both practical and economical.

● Because of this, it can also withstand higher boost pressures and power outputs, making it widely recognized in the tuning community as a “tough-to-use” material.

4.Disadvantages of Cast Iron Engine Blocks

While cast iron engine blocks are strong and durable, they also have limitations.

● First, they are relatively heavy. Cast iron has a high density and is significantly heavier than aluminum alloy cylinder blocks, which increases vehicle weight and hinders high-speed driving and fuel economy.

● Second, its heat dissipation performance is inferior to that of aluminum alloy, and its low thermal conductivity makes it prone to heat accumulation in the engine, requiring a more complex cooling system to maintain a normal temperature.

● Furthermore, cast iron is prone to rust, especially in humid environments or under long-term use. It requires coolant and coating protection to prevent corrosion.

● Finally, its thermal expansion characteristics differ significantly from other materials. If the engine design involves a combination of multiple materials, additional engineering measures must be implemented, otherwise reliability may be affected.

5.Cast Iron Engine Block Material Types

Common cast iron engine block materials include gray cast iron, ductile iron, and vermicular graphite iron.

Gray cast iron is the most widely used in traditional engines due to its low cost, excellent castability, and strong dimensional stability, and remains the most common cylinder block material.

Ductile iron, on the other hand, offers greater strength and toughness, allowing it to withstand higher combustion pressures. Vermicular cast iron is in between the two. It is stronger than gray cast iron and easier to process than ductile iron.

6.What casting process is generally used to produce cast iron engine blocks?

(1) Sand casting

Most cast iron engine blocks are cast using sand casting. The specific method is to first fill the mold with sand, then remove the mold to form two half molds, and then combine them to form a complete mold cavity. In order to form cavities such as piston holes and water channels inside the cylinder block, sand cores are also placed in the mold cavity. Then, molten cast iron is poured into the mold cavity. After cooling and solidification, the mold and core are disassembled to obtain a complete cast iron cylinder block. This process is low-cost and mature, and can meet the needs of complex structures and small and medium-sized batch production.

(2) Metal mold casting (permanent mold casting)

Metal mold casting uses durable metal molds that can be used repeatedly. When producing cast iron cylinder blocks, molten iron is poured into the metal mold and the mold cavity is filled by gravity. Compared with sand casting, the cast cylinder block has more precise dimensions, smoother surface and higher production efficiency, which is suitable for mass production or engine blocks with high dimensional accuracy requirements. Since the mold is strong and durable, repeated use can also reduce long-term production costs.

7.What are the differences and points to note in the manufacturing and processing of cast iron engine blocks and aluminum engine blocks?

There are some obvious differences between cast iron cylinder blocks and aluminum cylinder blocks in manufacturing and processing, and the points that need attention are also different:

(1) Casting

Cast iron is more sensitive to sand mold technology and cooling speed. It is necessary to control the ductile iron treatment, degassing and shrinkage problems, otherwise defects are likely to occur. Aluminum cylinder blocks are mostly die-cast or low-pressure casting, with low melting point and good fluidity. It is necessary to pay attention to uniform filling and pore control.

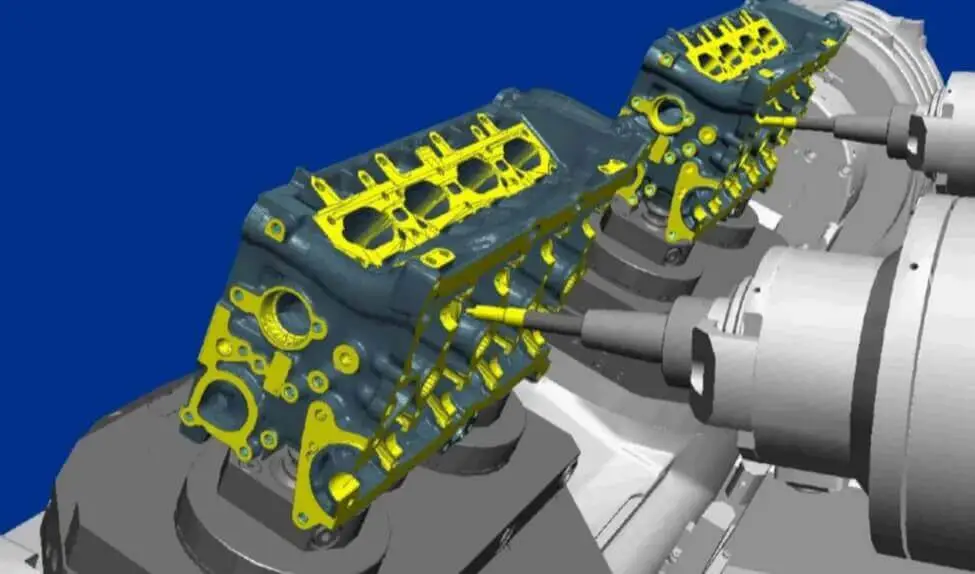

(2) Machining

Cast iron has high hardness and stable cutting, but vibration must be controlled during processing, otherwise it may affect the processing accuracy. Aluminum is soft and easy to stick to the knife. It is necessary to use special tools and adjust parameters such as cutting speed and feed rate to ensure smooth processing and surface quality.

(3) Post-processing

Cast iron cylinder blocks are usually heat treated and the inner bore is ground or honed to improve wear resistance and dimensional accuracy. Aluminum cylinder blocks often require sleeves or surface treatments in the cylinder bore due to their poor wear resistance, such as chrome plating, spray metallization, or ion deposition, to enhance wear resistance.

In general, cast iron cylinder blocks focus on strength and wear resistance, and the process is mature, but the cooling and defect control requirements are high; aluminum cylinder blocks focus on lightweight and processing accuracy, but require additional surface treatment to ensure durability.

8.What are the common faults and failure modes of cast iron engine blocks? How to repair them?

(1) Cylinder block cracks

Although cast iron is strong, the cylinder block may crack when the engine overheats, the coolant freezes, or is subjected to severe impact. Cracks often lead to coolant or oil leakage. Repairs generally use professional cold welding or brazing processes. In serious cases, the only option is to replace the cylinder block.

(2) Cylinder liner wear

Long-term operation, poor lubrication or impurities will accelerate the wear of the cylinder liner, which will manifest as oil burning and reduced power. Mild wear can be repaired by honing, and severe wear requires replacement of the cylinder liner.

(3) Cylinder bore deformation (deviation, ovalization)

The cylinder bore may gradually deform under high temperature and high pressure, becoming oval or offset, resulting in a decrease in compression ratio and poor engine performance. The repair method is to bore the cylinder and use a larger piston, or re-insert the sleeve to restore the shape.

(4) Cylinder thread damage

Long-term disassembly or over-tightening will cause the thread to slip or break, affecting the tightness of the cylinder head. The repair method is usually to use thread sleeves or inlay repairs to restore the original tightness.

9.Vehicles with Cast Iron Engine Blocks

Cast iron engine blocks still offer advantages in the following automotive applications. The following logic will guide the discussion: “Vehicle Category — Engine Type — Why Cast Iron Cylinder Blocks”:

● Heavy-Duty Trucks and Construction Machinery — Large-Displacement Inline-Six or V8 Diesel Engines — These engines operate under high loads for extended periods, requiring exceptional strength and durability. Cast iron offers excellent compressive strength and a long lifespan.

● Large Pickup Trucks and Full-Size SUVs — Large-Displacement V8 Gasoline or Diesel Engines — These engines emphasize traction and load-carrying capacity. Cast iron cylinder blocks offer excellent rigidity and can withstand high torque and compression ratios.

● Classic and Modified Vehicles — V8 Gasoline Engines — Cast iron cylinder blocks are typically designed from the factory and are also preferred for modifications because they maintain stability under high boost pressures and are less prone to cracking or deformation.

● Commercial vehicles and specialty vehicles (large trucks, special operation vehicles)—inline four- and six-cylinder diesel engines—are subject to harsh operating conditions and require long service lives. Cast iron offers excellent wear resistance, mature maintenance and repair methods, and higher reliability.

10.Summary

In general, while cast iron engine blocks are heavier and less heat-dissipating than aluminum alloys, they still offer significant advantages in strength, wear resistance, and durability. Whether for heavy-duty vehicles, engines subjected to long periods of high load, or the tuning community seeking high boost pressure and horsepower, cast iron engine blocks continue to demonstrate irreplaceable value. This is why they continue to be widely used in modern automotive manufacturing.

Choose LVXUN as your engine block manufacturer

Choosing LVXUN as your engine block manufacturer is more than just finding a parts supplier; it’s gaining a trusted, long-term partner. We offer:

Various Material Options

Whether you need a cast iron block for high strength and durability, or an aluminum alloy block for lightweighting and fuel efficiency, we can meet your needs.

Flexible Casting Processes

We have a variety of mature processes such as sand casting, metal mold casting, die casting, low-pressure casting, gravity casting, etc., and can customize the most suitable production plan according to different needs.

Extensive Manufacturing Experience

With years of experience specializing in engine block manufacturing, we have accumulated comprehensive process control and processing expertise, ensuring the stability and reliability of every product.

Strict Quality Control

From casting to post-processing, every step is rigorously inspected to ensure the blocks offer exceptional wear resistance, precision, and consistency.

Choosing us means your products not only have reliable quality and performance, but also gain a long-term competitive advantage in the market.

FAQ:

Why paint an engine block?

Painting an engine block primarily protects and enhances performance. The paint protects against moisture, mud, and road salt, preventing rust and corrosion. Specialized coatings also help dissipate heat, ensuring more stable engine operation in high-temperature environments. Furthermore, painting creates a cleaner appearance and makes it easier to detect leaks or cracks.

Does a cast iron engine have a longer lifespan?

Generally speaking, cast iron engine blocks tend to last longer than aluminum alloys. This is because cast iron has higher fatigue strength and wear resistance, better resistant to thermal expansion and contraction, vibration, and long-term wear. Therefore, it tends to be more durable under the same conditions.

Can cast iron engine blocks crack? Why do they crack?

Cast iron blocks can crack. Common causes include excessive thermal stress from engine overheating, metal fatigue caused by frequent temperature fluctuations, internal casting defects (such as pinholes, shrinkage holes, and air holes) that weaken the structure, and mechanical shock or stress concentration in the bolt area. Cracks typically appear in weak areas such as waterways, bolt holes, or the edges of the combustion chamber.

What are the advantages of cast iron blocks when modifying (for high boost pressure and horsepower gains)? Why are they so popular among enthusiasts?

Cast iron blocks offer superior rigidity and pressure resistance, making them less susceptible to deformation or cracking under high boost and combustion pressure conditions, allowing them to withstand higher power outputs. This provides a greater safety margin in engine modifications, making them a popular choice among performance car enthusiasts.

What do you think?

[…] Cast iron cylinder blocks perform well under high load and high temperature conditions and are suitable for high-performance and heavy-duty engines. […]