High pressure die casting process: the key to building quality metal parts

High pressure die casting(HPDC) has become one of the most commonly used metal forming technologies in the manufacturing industry due to its excellent efficiency and precision. It can produce complex and dimensionally accurate metal parts with extremely high repeatability and is widely used in various industrial fields.

So how does this process unfold? First, the selected metal material (such as aluminum, zinc, magnesium or copper) needs to be heated to a molten state. Then, the molten metal is quickly injected into a pre-designed mold cavity under extremely high pressure. The metal quickly cools and solidifies in the mold, forming a part contour that is exactly the same as the mold.

If you are considering introducing high-pressure die casting technology in your next project, this article will provide you with a clear process overview to help you better evaluate its advantages in practical applications.

1.Definition and characteristics of high pressure die casting process

(1) definition

High pressure die casting process is a kind of process technology through the molten metal under high pressure quickly injected into the mold cavity, and then cooled and solidified to form castings. The core of high pressure die casting process lies in its high pressure and high speed filling process, which makes the liquid metal can fill every corner of the mold in a very short period of time, so as to form a dense organization, the surface of the casting.

(2) Main features

1) high pressure and high speed filling

High pressure die casting process using high pressure (usually in 15-100MPa) will be molten metal alloy into the mold cavity.

Liquid metal to high speed (10-50 m / s, even more than 80 m / s) filling cavity, filling time is very short, about 0.01-0.2 seconds.

2) Precision molding

Capable of producing castings with high dimensional accuracy and good surface finish, which can usually be used without subsequent mechanical processing.

Complex structures such as threads can be cast, and it is suitable for casting of highly fluid metals.

3) Mass production and economic efficiency

High machine productivity, a mold with multiple cavities, easy to realize mechanization and automation, suitable for mass production.

Due to the casting size is accurate, the surface is bright and clean, reduce the processing equipment and man-hours, improve the utilization rate of metal.

2.High pressure die casting process principle and flow

(1) process principle

The basic principle of high pressure die casting process is the use of high pressure will be molten metal liquid quickly pressed into the mold cavity, the metal liquid in the high pressure rapid cooling and solidification, the formation of a predetermined shape. In this process, the flow and solidification of the liquid metal are strictly controlled to ensure the quality of the castings.

(2) Process Flow

1) Mold preparation:

The mold needs to be preheated to working temperature to ensure the fluidity of the liquid metal filling and the quality of the casting. The preheating temperature and time of the mold need to be optimized according to the specific alloy material and casting structure to ensure that the mold maintains a stable temperature field during the die casting process.

2) Close the mold:

Die casting machine’s moving mold and fixed mold closure, forming a complete cavity. Closing process need to ensure that the mold alignment accuracy and clamping force, in order to avoid in the high pressure filling process, such as leakage or flying edge problems.

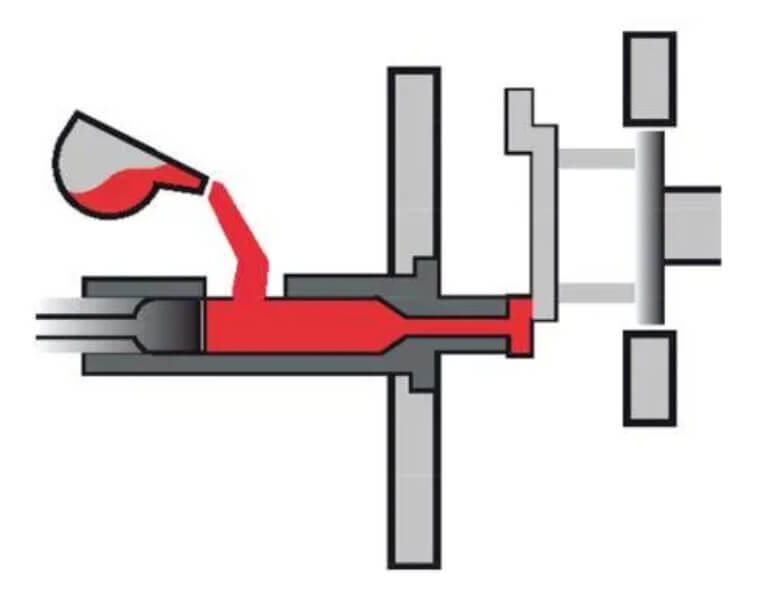

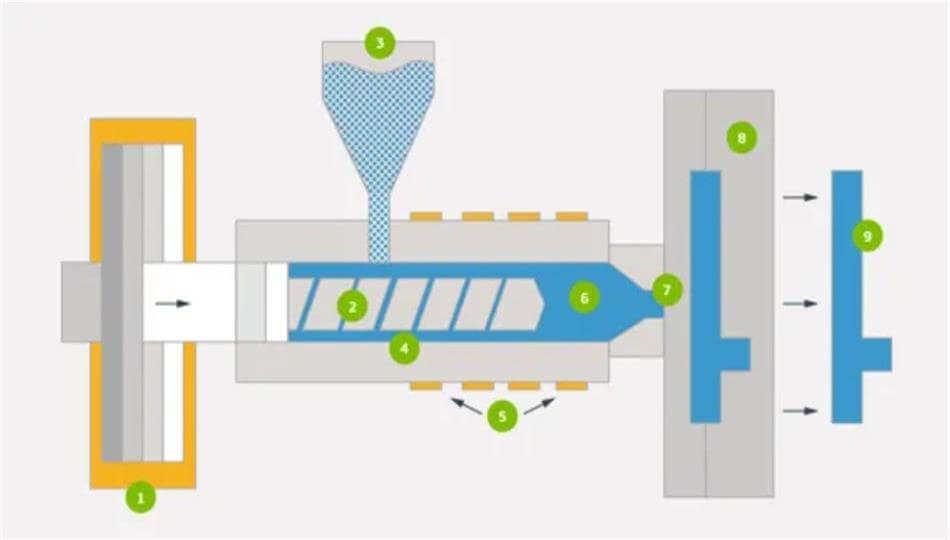

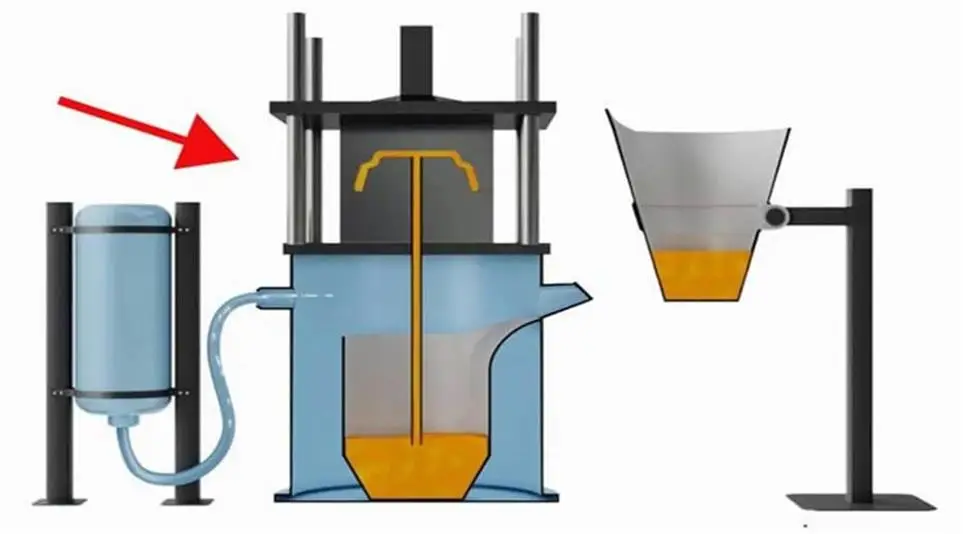

3) Injection:

The molten metal liquid into the cylinder of the die casting machine. The injection process needs to control the temperature and flow of the metal liquid, in order to ensure that the metal liquid in the filling process has enough fluidity and temperature uniformity.

4) Pressure injection:

Through the die casting machine’s pressure injection mechanism, the metal liquid with high pressure and high speed injected into the mold cavity. Pressure injection process need to accurately control the pressure injection speed and pressure injection, in order to ensure that the metal liquid can uniformly fill every corner of the mold, to avoid underfilling or pores and other defects.

The process of molten metal gradually filling the mold cavity

5) Cooling and solidification:

Liquid metal is rapidly cooled and solidified in the mold to form castings. The cooling process needs to control the cooling speed and temperature distribution of the mold to ensure the solidification quality and internal structure of the casting.

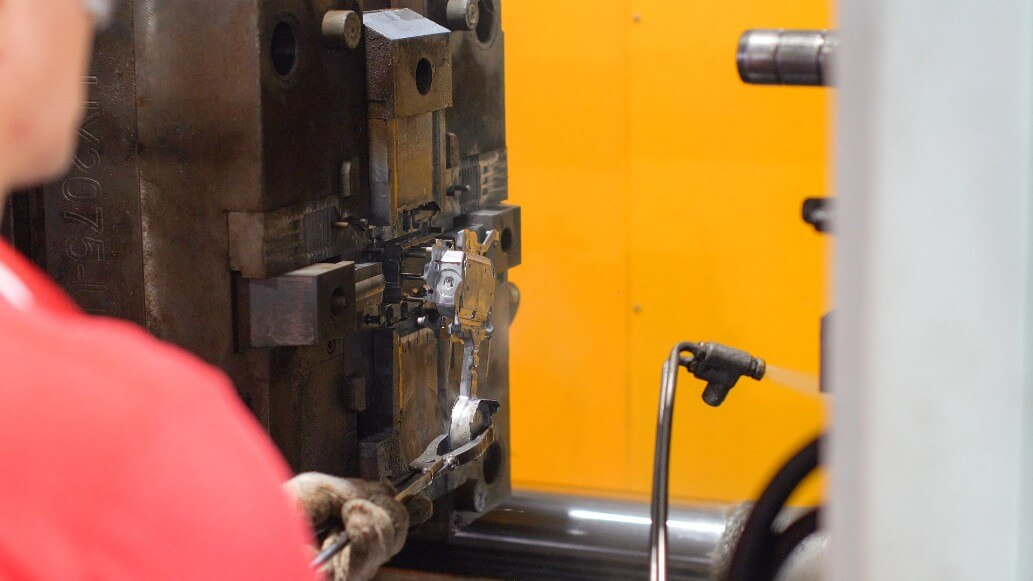

6) Mold opening and ejection:

After the casting is completely solidified, die casting machine to open the mold, and through the ejector mechanism will casting from the mold ejector. Mold opening and ejecting process need to ensure the integrity of the casting and surface quality, to avoid damage or deformation and other problems.

7) post-treatment:

Necessary post-treatment of die castings, such as deburring, surface treatment, heat treatment, etc., in order to improve its dimensional accuracy, surface quality and mechanical properties. Post-treatment process needs to be selected and optimized according to the specific requirements of the casting, in order to ensure that the die casting can ultimately meet the requirements of use.

3.Setting and analysis of seven important parameters of high pressure die casting process

(1) Melt holding time

The melt holding time refers to the duration of time that the metal is in a molten state in the furnace. This stage not only determines the uniformity of the metal temperature, but is also the key to removing impurities.

When the metal is left at high temperature, light impurities and oxides will naturally float to the surface of the liquid, and we will remove them by skimming.

In addition, due to the different melting points and oxidation reaction rates of different metals (such as aluminum, zinc, and magnesium), different holding times should be set for different metals.

The general range of common alloy melting temperatures is as follows:

Aluminum alloy: 660℃~730℃

Zinc alloy: 390℃~430℃

Magnesium alloy: 640℃~690℃

LVXUN Casting has advanced casting equipment, professional personnel technology, and rich experience in parts production. We only use high-quality furnaces. This ensures that every metal we process can reach a pure state without impurities.

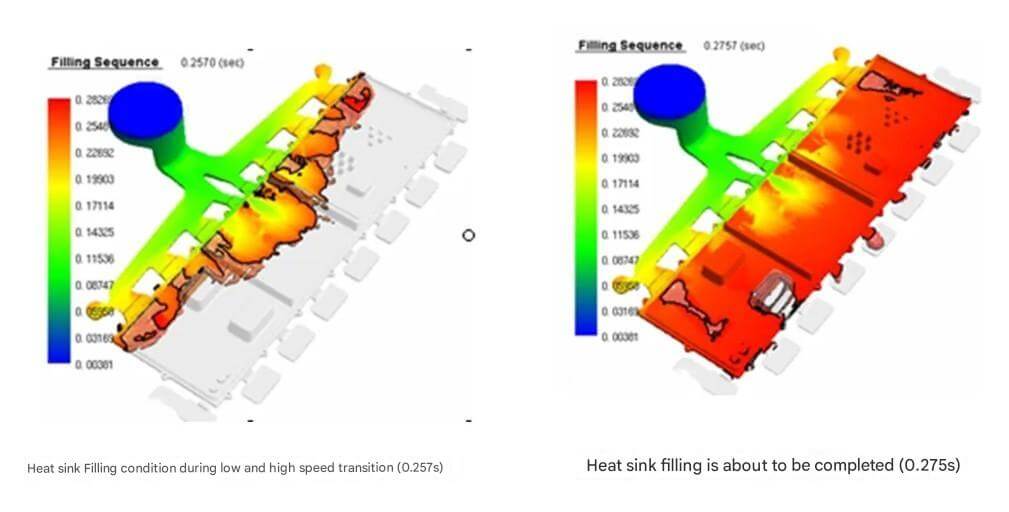

(2) Filling speed

Filling speed is the speed at which molten metal enters the mold. During this process, high-temperature molten metal enters the mold along the channel. Please note that in the first stage, gas is easily drawn in, causing defects in the casting. Therefore, a two-stage injection control is generally adopted – low speed start to facilitate exhaust, high speed pressurization to quickly fill the cavity. This not only ensures high efficiency but also avoids surface defects.

(3) Pouring time

At the same time, the control of pouring time is also crucial. Pouring time refers to the time required for molten metal to fill the cavity from being injected into the die casting mold. The pouring time varies depending on the type of part. For example, the filling time of galvanized parts is 0.02 seconds, while the filling time of fuel injection parts is 0.04 seconds. In order to produce high-quality product parts, our LVXUN can achieve precise injection time management through a computer-controlled die-casting system to ensure consistency.

(4) Mold temperature and preheating

Mold temperature control has a direct impact on casting quality and mold life. Too low will cause insufficient filling, cracks and cold shut, while too high will easily lead to thermal fatigue of the mold or even premature failure.

Mold temperature is usually controlled between 150 and 300℃. In the actual production process, we will also use a preheater to heat the mold to reach the production preparation state.

(5) Pressurization and pressure holding control

The pressurization stage refers to the process of continuing to apply pressure after metal filling, which is used to promote the metal to fully fill the mold details. Parts with high precision requirements often need to pay attention to this step. After pressurization, pressure holding is carried out again. The purpose of pressure holding is to compensate for shrinkage and prevent the formation of shrinkage cavities.

The length of the pressure holding time should be set according to the wall thickness of the part and the cooling characteristics of the metal, generally between 1 and 15 seconds. Reasonable pressurization and pressure holding control can significantly improve the density and strength of the casting.

(6) Gate and riser design

The gate (gate) is the channel for molten metal to enter the mold cavity. Its size and position determine the filling speed and flow direction of the metal;

The riser (vertical pipe) plays a role in shrinkage compensation during the solidification stage. The problem of pores and shrinkage holes in castings can be solved by optimizing the gate and riser structure.

(7) Degassing treatment

As mentioned above, it is easy to get gas involved in the high-pressure injection process. If it is not removed in time, defects such as pores will form after solidification.

For this reason, we usually use degassing tablets or inert gas (such as argon) treatment to remove gas in production. Especially for aluminum alloys, the degassing process is particularly critical.

After the above introduction, do you also think that the high pressure die casting process is a very technically demanding metal forming process? Problems in any link will lead to poor quality of metal parts. Of course, a mature casting company can completely avoid these defects with rich experience, so in order to ensure that your parts do not fail, please be sure to hire an experienced company to produce high-quality and reliable parts.

4.Analysis of the advantages and limitations of high pressure die casting process

High pressure die casting is a forming technology that injects molten metal into a metal mold at extremely high speed and pressure.

This process can achieve high-precision replication of complex structures and fine details, and is particularly suitable for industrial products that require high dimensional accuracy and excellent surface quality.

Since the molten metal can fully fill the mold cavity under high pressure drive, even tiny corners can be filled with metal, which ensures the compactness and integrity of the product. Therefore, based on the above characteristics, high pressure die casting is very suitable for manufacturing precision, thin-walled, lightweight parts.

Another significant advantage of this process is the extremely short production cycle. Each production cycle of high pressure die casting is extremely short, making it very suitable for mass production scenarios.

In addition, the castings produced by computer-controlled die-casting machines have a smooth surface, which reduces subsequent processing steps. For products that require electroplating or coating treatment, they have natural adaptability, greatly reducing the subsequent surface treatment costs.

Although high pressure die casting has many advantages, it also has certain limitations. The most prominent problem is the high initial investment, including mold design and manufacturing and investment in special equipment, so it is more suitable for large-scale production. For single or small batch orders, this process is not cost-effective.

In addition, castings are prone to internal pores during high-pressure injection. These defects may affect subsequent heat treatment or welding processes, because under high temperature conditions, the expansion of gas in the pores may cause cracks or structural failure in the casting.

However, if the part must be heat treated, this requirement can also be achieved through the optimal combination of process parameters, of course, this is very technical. In addition, I also recommend a solution. If your parts are in medium batches, you can also use gravity casting to produce them. Gravity castings can be heat treated.

Another limiting factor is the scope of material application. High-pressure die casting is generally only suitable for low-melting-point metals with good flow properties such as aluminum, magnesium, and zinc, but not for high-melting-point materials such as steel or copper.

5.High pressure die casting process commonly used materials selection

(1) commonly used die casting alloy

High pressure die casting process commonly used alloys including aluminum alloy, zinc alloy and magnesium alloy. These alloys have good mobility and formability, can fill the complex mold cavity under the condition of high pressure and high speed.

Aluminum alloy because of its good strength and corrosion resistance, in the automotive and aerospace industry in a wide range of applications; zinc alloy because of its low cost and easy to process, commonly used in electronic products and small structural parts; magnesium alloy with its lightweight and high-strength characteristics in portable electronic equipment and high-performance automotive components are widely used.

(2) material performance requirements

Die casting material selection need to take into account its fluidity, mechanical strength, heat resistance and corrosion resistance and other performance requirements. Good fluidity to ensure that the material can fill every detail of the mold, and high mechanical strength is to ensure that the casting in the use of the process can withstand a variety of loads and the environment of the necessary conditions. In addition, the thermal stability and corrosion resistance of the material is also an important factor to consider when choosing die casting materials, especially in high temperature or corrosive environment castings.

6.High pressure die casting process equipment and molds

(1) the classification and selection of die casting machine

High-pressure die casting machines are mainly divided into two categories: cold chamber die casting machines and hot chamber die casting machines.

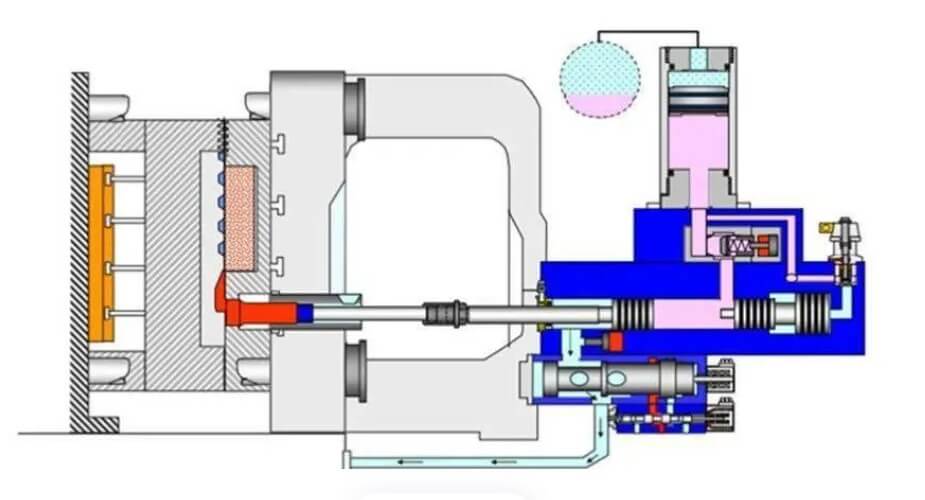

Cold chamber die casting is usually used to process metals with higher melting points, such as aluminum, brass and magnesium. In this process, the metal is melted outside the mold system, and then the molten metal is poured into the injection cavity by manual or automatic devices.

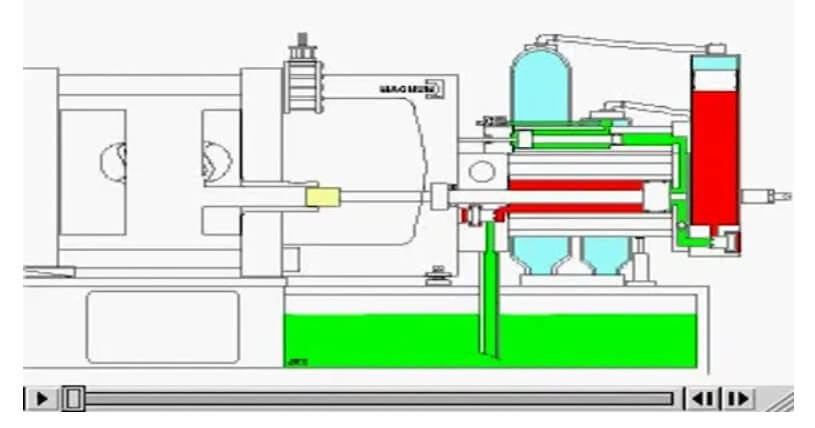

Horizontal cold chamber die casting machine

Although this method is suitable for higher temperature materials and can cast larger parts, the overall production cycle is relatively slow because the metal transfer process is an independent link.

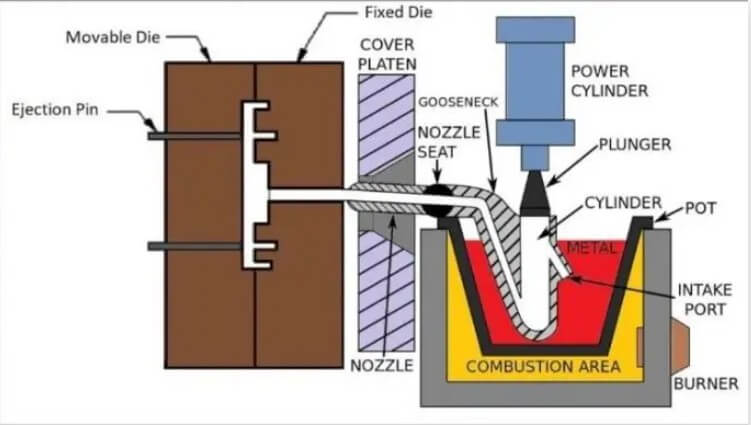

Relatively speaking, the structure of hot chamber die casting is more compact. It sets the injection system directly in the integrated furnace, so that the metal remains in a liquid state in the furnace and can be quickly injected into the mold. This design significantly improves the die casting rhythm and production efficiency.

Hot Chamber Die Casting

However, due to the long-term direct contact between the metal and the furnace, there is a risk of metal impurities contaminating the system, so hot chamber die casting is more suitable for alloys with lower melting points and better chemical stability, such as zinc, magnesium and lead.

(2) mold design and manufacture

Die casting mold design and manufacture is the key link in the high pressure die casting process. Mold design needs to accurately calculate the size of the cavity and the layout of the cooling system, in order to ensure the quality of castings and production efficiency. The choice of mold material is also very important, need to have high hardness, wear resistance and thermal fatigue resistance. Mold manufacturing process including mold design, mold processing, mold assembly and mold debugging steps, each step need to strictly control the quality, in order to ensure the service life of the mold and production stability.

7.High pressure die casting process application areas

(1) automobile industry:

Automobile industry is one of the most widely used high pressure die casting process. With the energy saving and emission reduction and lightweight trend continues to promote, die casting aluminum alloy in the automotive parts manufacturing application is increasing. Typical products include engine block, transmission housing, brake head, chassis and suspension system. These parts are produced through high-pressure die casting process, with high dimensional accuracy, high strength and light weight, can significantly improve the overall performance of the car.

(2) Communication industry:

With the popularization of 5G communication technology, smart phones, tablet PCs and communication base stations and other equipment demand surge. Die casting process plays an important role in the manufacture of shells, frames and internal structural parts of these products. The high precision and excellent sealing and heat dissipation properties of die castings ensure the stable operation and aesthetics of communication equipment.

(3) home appliance industry:

In the field of home appliances, high pressure die casting process is widely used in the production of air conditioner shell, refrigerator handle, washing machine drum and other key components. The high strength and precise size of die castings not only enhance the durability and appearance quality of home appliances, but also effectively improve production efficiency and reduce costs.

(4) electronics industry:

High pressure die casting process in the electronics industry is mainly used for the production of a variety of shells, frames and structural parts, such as computer chassis, server shells, LED lamps and lanterns. Die casting excellent conductivity and high precision, to meet the special needs of electronic products for heat dissipation and electromagnetic shielding.

(5) medical equipment industry:

Because of the high precision and good corrosion resistance of die casting, so in the field of medical equipment has also been widely used. For example, high pressure die casting process can be used to produce surgical instrument frames, medical equipment shell and other high-demanding parts, to ensure product safety and reliability.

(6) aerospace industry:

In the aerospace field, high pressure die casting process is used to manufacture aluminum alloy and magnesium alloy parts and components with high strength and lightweight characteristics, such as aircraft engine parts, landing gear and so on. The high performance requirements of these parts make the die casting process indispensable in the aerospace manufacturing industry.

8.Based on product requirements, what improved processes have been derived from the high pressure die casting process?

According to the performance requirements and design complexity of different products, some targeted improvements will be made to the high pressure die casting process. Among them, vacuum die-casting, multi-stage injection and semi-solid metal processing are the three most representative improvement methods. The following will analyze them in detail:

(1) Vacuum die-casting

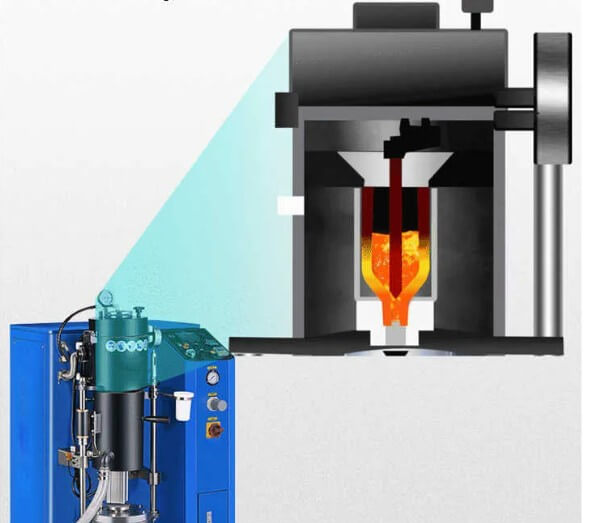

Vacuum die-casting is to add a cavity vacuum pumping step to the standard high pressure die casting process. Due to the high-speed filling of the mold in traditional high pressure die casting, the air in the mold cavity is often trapped in the molten metal, which is easy to form pores.

Vacuum die-casting removes the air inside the mold before injection, allowing the molten metal to flow in a lower air resistance environment, thereby fundamentally and significantly reducing gas inclusions. It is especially suitable for automotive structural parts, motor housings and other parts with high air tightness requirements.

Remove the air from the mold before injection

(2) Multi-stage injection technology

Multi-stage injection technology optimizes the injection control system of the high pressure die casting machine and divides the entire injection process into multiple stages, usually including low-speed starting, medium-speed filling and high-speed compaction.

Compared with the traditional single-speed injection, this multi-stage control can better match the flow speed of the metal liquid, avoiding the impact of the metal liquid on the mold cavity and causing problems such as flash and pores. At the same time, it can also extend the service life of the mold.

(3) Semi-solid metal processing

Semi-solid metal processing is a more advanced process method. We all know that the metal raw materials usually used in the casting process are in a liquid state, and the semi-solid processing technology is special in that it can control the metal in a partially molten solid-liquid coexistence state, and then form it through the die-casting equipment.

Then someone asked, what is the advantage of doing this? Compared with full liquid die casting, semi-solid die casting has a more uniform metal flow rate and gentler mold filling during the injection process, thereby significantly reducing the risk of pores and cracks. In layman’s terms, it has a smaller shrinkage rate and higher dimensional accuracy, which is very suitable for high-end manufacturing. However, the equipment and technical threshold of the semi-solid process are also relatively high.

9.Summary

Through the introduction of the above information, you can completely know the high pressure die casting process with its excellent performance and wide range of applications, has become an indispensable part of modern metal processing. Through continuous technological innovation and optimization, high pressure die casting process will continue to provide high quality, reliable metal parts for various industries.

What do you think?

This design is wicked! You obviously know how to keep a

reader amused. Between your wit and your videos, I was almost

moved to start my own blog (well, almost…HaHa!) Wonderful job.

I really loved what you had to say, and more than that, how you

presented it. Too cool!

I used to be recommended this website by means of my cousin. I am

now not certain whether this put up is written by way of him as no one else understand such special about my

trouble. You’re amazing! Thanks!

[…] surface treatment is an indispensable part of the casting process. It has a direct and significant impact on the performance, appearance and service life of […]

[…] die casting process is an efficient, precise and reliable metal forming technology, widely used in automobiles, […]

[…] High-pressure die casting is an efficient metal forming technology. Its basic principle is to inject liquid metal into the mold cavity at high temperature, high pressure and high speed, and quickly cool and solidify to form a casting. This technology can produce metal parts with complex shapes and precise dimensions, and is widely used in many fields such as automobiles, electronics, and aerospace. […]