What is Metal Casting Shrinkage? In-depth Study and Comprehensive Analysis

Are you often confused? Why are my castings always inaccurate in dimensional accuracy, deviating from the dimensions on the drawings, and often with shrinkage holes, shrinkage and deformation on the surface. This is actually because the physical phenomenon of casting shrinkage is not taken into account during the metal casting process.

In the casting process, metal casting shrinkage is a common physical phenomenon that must be controlled. Whether it is gravity casting, pressure casting or investment casting, the volume of metal will decrease to varying degrees when it solidifies from liquid to solid.

Why are some manufacturers able to produce castings with excellent surface quality? It is because they understand that if this volume change is reasonably predicted and controlled, the casting will avoid dimensional deviation, deformation and even internal defects. At this point, we at LVXUN have rich practical experience and can completely avoid the occurrence of defects.

This article will start from the basic principles of metal casting shrinkage, and then analyze the differences in shrinkage rates of different metal materials. For the problem of avoiding defects in castings, different metals and different casting methods have different solutions. Therefore, only by understanding the root cause of shrinkage can we prescribe the right remedy.

Table of Contents

What is metal casting shrinkage?

Metal casting shrinkage refers to the phenomenon that the volume or size of metal decreases during the process of cooling from high-temperature liquid to room-temperature solid. According to the different stages of occurrence, casting shrinkage can be divided into the following three stages:

(1) Liquid shrinkage

Refers to the volume change of metal from the high-temperature pouring temperature to the beginning of solidification of the metal.

Although this stage is usually controlled by the shrinkage feeding system (such as riser), if the fluidity is insufficient, it may still cause shrinkage or cold shut.

(2) Solidification shrinkage

The volume change caused by the metal changing from liquid to solid is the main source of shrinkage defects.

If the shrinkage feeding design is unreasonable, shrinkage cavities and shrinkage are very likely to form.

(3) Solid state shrinkage

At this stage, the metal has completed solidification. The next step is to cool from the solidification temperature to room temperature. In this process, linear or volume shrinkage will also occur.

The shrinkage at this stage directly affects the final dimensional accuracy of the casting.

After introducing these three shrinkage processes, you will find that metal casting shrinkage is not a single process, but a physical change throughout the entire cooling process, involving multiple factors such as the cooling of the material itself, the design of the shrinkage feeding system, and the process control during the entire casting process.

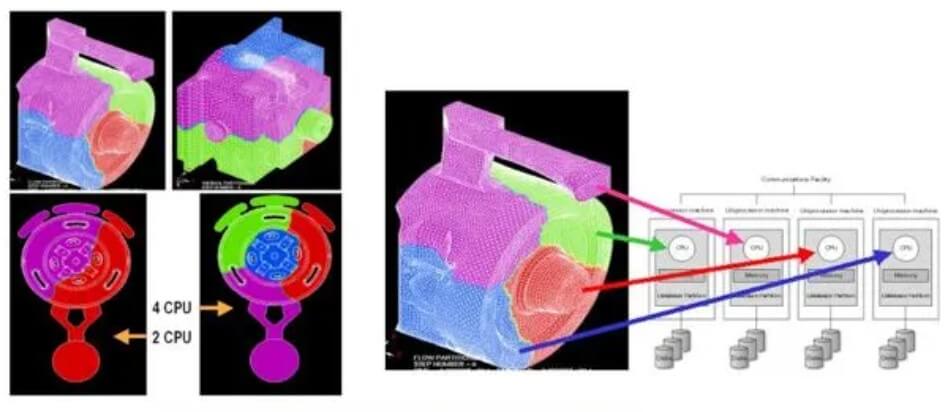

How to avoid casting shrinkage? How to set up the shrinkage feeding system?

In the previous paragraph, the shrinkage feeding system was mentioned many times. In fact, a well-designed shrinkage feeding system can solve most casting defects.

The core of the shrinkage feeding system is to ensure that there is enough liquid metal to continuously compensate for the volume loss caused by shrinkage during the solidification process by properly arranging the riser.

(1) The basic principle of shrinkage feeding

Casting shrinkage mainly occurs in the metal solidification stage. When the last part of the casting begins to solidify, if the metal has completely lost its fluidity at this time, shrinkage cavities or shrinkage pores will be formed because there is no liquid metal to supplement the missing volume.

The design objectives of the shrinkage feeding system are:

Ensure that the casting starts to solidify from a distance away from the riser and moves towards the riser. The riser is the last solidification area and continuously provides liquid metal to the casting.

(2) Key components of setting up a shrinkage feeding system

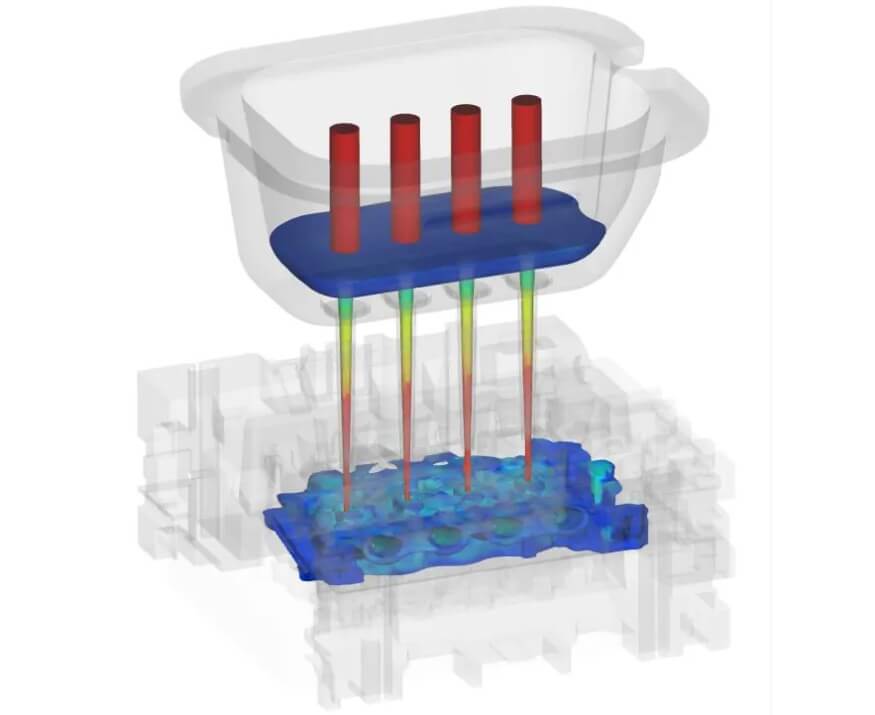

1) Riser design

● Open riser: suitable for sand casting; fast heat dissipation, metal solidification needs to be delayed by insulation or heating during the casting process;

● Closed riser (insulating riser): good insulation effect, suitable for castings that require strong shrinkage feeding, such as thick-walled castings.

● Blind riser (side riser): used for shrinkage feeding needs when thin walls, complex shapes, and space is limited.

2) Dimension design:

The riser size must ensure that the volume of the riser is greater than the shrinkage volume of the last solidified area of the casting;

3) Neck design

The neck is the part between the riser and the casting, and its function is to:

● Control the solidification order of the riser: if the neck size is small, the metal solidification of the riser will be slower.

● Improve shrinkage feeding efficiency;

● Facilitate the separation of the riser from the casting and reduce the workload of cleaning.

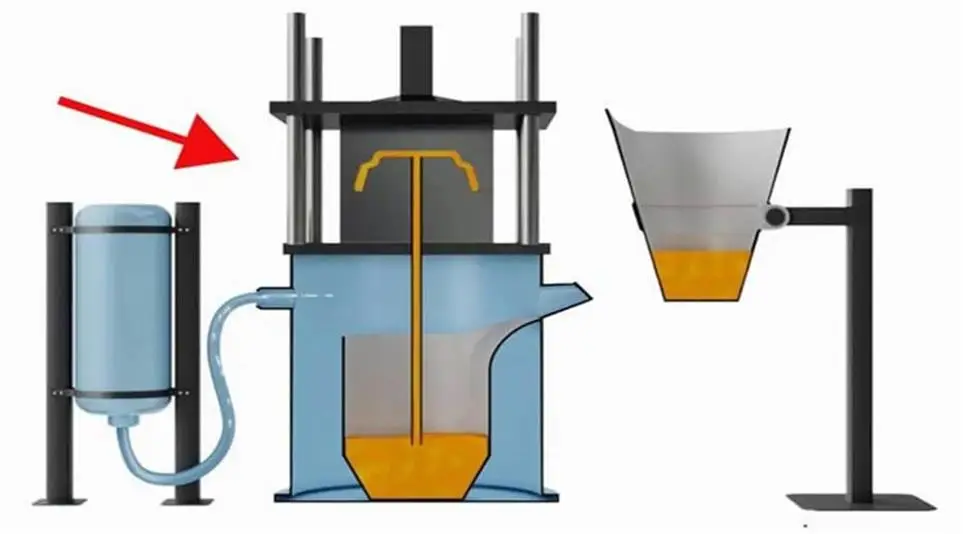

(3) Auxiliary measures to improve the shrinkage compensation effect

If you want to artificially control the solidification rate of the molten metal, you can take some auxiliary measures

● Insulation and heating technology

You can use insulation coatings, heated risers and other methods to increase the temperature of the riser and the shrinkage compensation time.

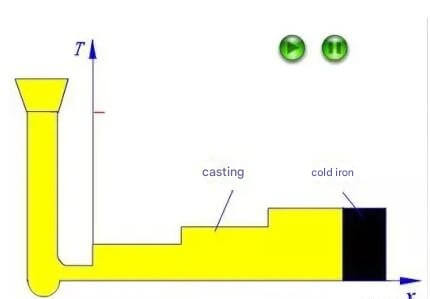

● Chill iron application

Use a chill iron (metal heat sink) near the riser to speed up the solidification rate of these areas;

(4) Design example diagram (text description)

Imagine a T-shaped casting with a thicker wall in the middle, thin-walled areas at both ends, and a hot node in the middle.

● The design steps are as follows:

Set a large closed riser at the top of the middle;

Design a necking section between the casting and the riser, with a cross-section of 40% of the bottom of the riser;

Set a chill iron near the thin-walled area to make it solidify in advance;

Use coatings or heating to extend the solidification time of the riser.

This design can ensure that the casting solidifies from the edge to the center and from the far end to the riser, and finally the riser is fully compensated to avoid the formation of shrinkage cavities.

What effects will metal casting shrinkage have on castings?

Casting shrinkage is one of the root causes of casting defects and dimensional errors. It mainly brings the following effects:

(1) Decreased dimensional accuracy

If shrinkage compensation is not reserved, the casting size will be smaller than the design drawing, and in severe cases, the parts will be directly scrapped. At the same time, the shrinkage rate must also be considered when designing the mold. Different metals and different parts shrink differently. How much shrinkage space should be reserved should be taken into account when designing, otherwise the shape and position tolerances will exceed the standard. Especially for parts with high precision requirements, the final size must be extremely close to the drawing size tolerance, and the final size can only be larger than the drawing size, otherwise secondary finishing cannot be performed.

(2) Structural defects: shrinkage and shrinkage

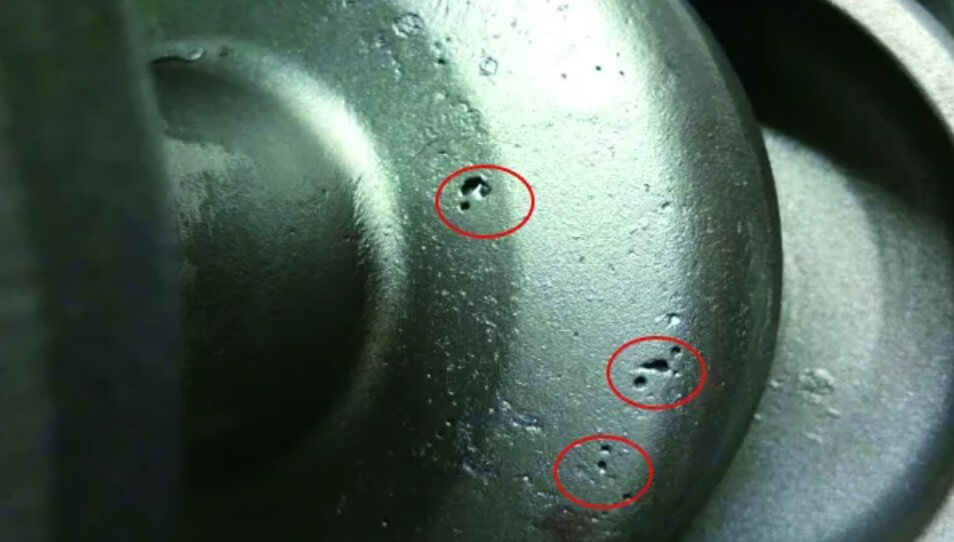

Shrinkage: usually occurs in the last solidified area. Because there is no metal to supplement the missing metal, visible holes are formed inside.

Shrinkage: fine pores formed when the volume is reduced. Although it is difficult to observe with the naked eye, it will reduce the strength. For areas with high precision and high strength requirements, such defects will seriously affect the mechanical properties and sealing of castings, and even lead to scrapping.

(3) Residual stress and deformation

Uneven cooling and shrinkage lead to residual stress inside the casting; especially for castings with asymmetric structures or large differences in wall thickness, deformation, warping or cracking are prone to occur.

(4) Increased machining allowance

In order to avoid shrinkage resulting in substandard finished product dimensions, it is often necessary to increase the casting size reserve and increase the machining allowance. Although this solution is a safe solution, it will lead to material waste and increased processing costs.

Is there a difference in casting shrinkage rates of different metals?

Above we talked about the principle of metal casting shrinkage. We can improve the defects caused by metal shrinkage by scientifically setting up a shrinkage compensation system. We also talked about the impact of metal casting shrinkage on castings, so we must avoid this impact. Next, we will analyze the differences in casting shrinkage rates of different metals and alloys from a practical perspective, so as to adopt different response plans based on these differences.

The casting shrinkage of different metals and alloys varies significantly, which is determined by their respective physical properties. The following is a table of average linear casting shrinkage for commonly used metal materials in die casting (unit: %). Due to the extremely fast cooling speed of the mold during die casting, the shrinkage is usually less than that of sand casting or gravity casting, but it still shows significant differences due to material differences:

| Metal Material | Average Linear Shrinkage Rate (Die Casting) | Characteristics Description |

| Aluminum Alloys (ADC12, A380, etc.) | 0.6–0.9% | Preferred material for die casting; exhibits good fluidity, low shrinkage rate, and excellent dimensional stability. |

| Zinc Alloys (Zamak 3, ZL0410, etc.) | 0.4–0.6% | Extremely low shrinkage; suitable for high-precision die castings with long mold life. |

| Magnesium Alloys (AZ91D, etc.) | 0.7–1.0% | Lightweight material; fast cooling but slightly higher shrinkage, prone to internal stress. |

| Copper Alloys (Die-Cast Brass) | 1.2–1.5% | High strength but prone to oxidation; higher shrinkage rate requires strict mold design. |

| Lead-Tin Alloys (Low Melting Point) | 0.4–0.6% | Low shrinkage rate; suitable for precision electronic components. |

Aluminum alloy is the most widely used metal for die casting. It has a moderate shrinkage rate, and aluminum alloy die castings are used in many fields. Zinc alloy has an ultra-low shrinkage rate in die casting, so zinc alloy die castings are very suitable for parts with extremely high dimensional accuracy requirements; magnesium alloy and copper alloy have a high shrinkage rate, so it is necessary to optimize the mold design and reasonably design the shrinkage compensation method. The second part of the article mentions how to design it in detail. If you want to know more detailed information, please consult our LVXUN engineers and we will give you professional answers.

Summary

Metal casting shrinkage is an inevitable but controllable physical phenomenon. Only by understanding its formation mechanism, mastering the shrinkage characteristics of different metals, and reasonably applying them in mold design and shrinkage compensation systems can high-quality and high-dimensional consistency castings be produced. We at LVXUN have deeply realized this. For many years, we have been researching how to better avoid casting defects and provide our customers with higher-quality castings. Of course, we have not let our customers down. Especially for precision castings and complex structural parts, we will pay more attention to shrinkage management throughout the entire process.