Why Choose 535 Aluminum Castings? An In-Depth Analysis of Performance and Applications

Among the many aluminum alloy casting options, 535 aluminum castings, thanks to its high magnesium and low silicon material composition, offer exceptional corrosion resistance and excellent processing properties. Compared to more common A356 or A380, 535 achieves a more uniform, matte surface finish after anodizing and is stable in wet or salt spray environments.

This article systematically introduces the basic information, performance characteristics, and typical applications of 535 aluminum alloy. It also discusses its applications in sand casting and how to optimize casting surface properties through anodizing, spraying, or powder coating.

Table of Contents

1.535 Aluminum Specifications

Name and Standard Code

| Name / Code Type | Specific Identification |

| Alloy Name / Common Name | 535.0 / Almag-35 |

| Old Standard / Former Name | AMS 4238A, 4239; ASTM GM70B |

| UNS Number | UNS A05350 |

| Government Standard | QQ-A-601, QQ-C-371, etc. |

| ASTM | ASTM B26-98 |

Chemical Composition (Composition Range)

| Element | Content Range |

| Magnesium (Mg) | Maximum, 6.5 – 7.5% |

| Manganese (Mn) | 0.25 – 0.35% |

| Titanium (Ti) | 0.15 – 0.25% |

| Silicon (Si) | Approximately 0.15% |

| Iron (Fe) | 0.25 – 0.50% |

| Copper (Cu) | Low, generally ≤ 0.05 – 0.15% |

| Zinc (Zn) | Small amount, approximately ≤ 0.15% |

| Beryllium (Be) | 0.003 – 0.007% Beryllium |

| Boron (B) | Less than 0.005% |

| Other Impurities / Total Residues | ≤ 0.15%, etc. Aluminum (Al) is the remainder. |

2.535 Aluminum Alloy Performance Characteristics

No heat treatment required: The alloy achieves the required strength, corrosion resistance, and other properties in the “as-cast” (F temper) state.

Excellent corrosion resistance: Exceptional performance in marine environments, humid environments, salt spray, or chemically corrosive media. The material’s high magnesium content and low silicon impurities contribute to corrosion resistance.

Excellent machinability: The low silicon content reduces tool wear and stabilizes chip performance during machining (turning, milling, and drilling); provides excellent surface finish; and offers excellent appearance after polishing and anodizing.

Strong dimensional stability: Minimal deformation after casting, and less sensitive to heat treatment, cooling rates, and wall thickness than some Al-Si alloys. Suitable for parts requiring high precision or stability (such as instrument housings and marine components).

Excellent strength-to-weight ratio: Despite its light weight, it boasts the highest strength among cast aluminum alloys. Ideal for applications requiring lightweight, corrosion resistance, and high load-bearing properties that are unsuitable for heavy metals.

Standard mechanical properties

Most of these properties are typical values evaluated at room temperature using “cast” or “sand” general-purpose specimens. The specific values are as follows:

| Performance Indicator | Typical Value / Reference Value |

| Tensile Strength | 270-280 MPa (approximately 39-40 ksi) |

| Yield Strength | 140 MPa (approximately 20-21 ksi) |

| Elongation | 10-13% |

| Hardness | Approximately 70 HB |

| Shear Strength | 28-30 ksi (approximately 190-200 MPa) |

| Compressive Yield Strength | Approximately 35 ksi (approximately 240 MPa) |

| Elastic Modulus | Approximately 67 GPa (≈ 9.7×10⁶ psi) |

| Density | Approximately 2.60-2.66 g/cm³ |

3.535 Aluminum Casting Typical Uses

Applications in Marine Equipment

535 aluminum castings have relatively clear and unique application areas in the real industry. Its most typical use is in marine-related components, such as ship fittings, dock equipment, and offshore instrument housings. These applications require extremely high corrosion resistance. Due to its high magnesium content, 535 alloy exhibits far superior durability to most cast aluminum alloys in the face of salt spray and humid air, making it less susceptible to rapid corrosion and structural failure.

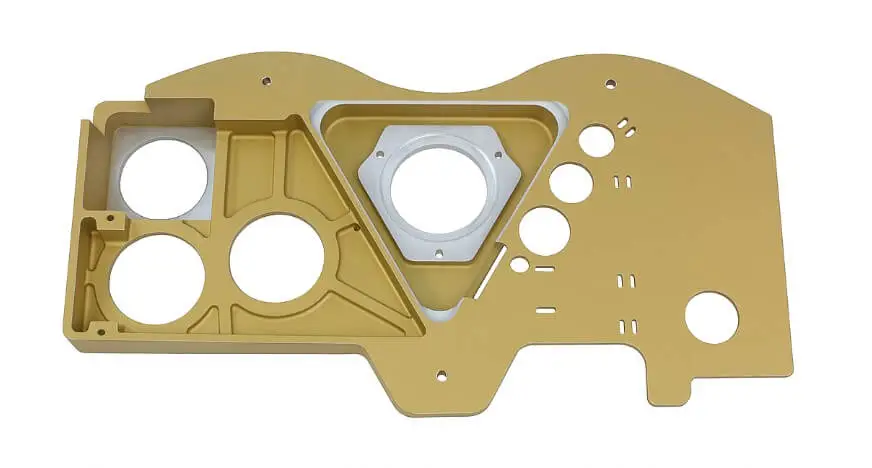

Applications in Precision Instruments and Meters

In the manufacture of precision instruments and meters, 535 is often used for housings and external frames. These products require high dimensional stability and machinability. 535 maintains good structural integrity after casting, making subsequent machining easier to control tolerances. Especially when secondary operations such as turning and milling are required, its cutting performance ensures a high surface finish, meeting the demands of precision assembly.

Applications in Transportation Equipment

In the transportation equipment sector, 535 aluminum castings are attracting attention due to their weight advantages. Compared to traditional cast iron or steel parts, it effectively reduces overall weight while maintaining sufficient strength and toughness, making it a popular choice for certain lightweight vehicle components and transportation equipment housings. The improved fuel efficiency and enhanced portability brought about by lightweighting are key factors in its popularity.

Applications in Some Military and Special Equipment

Furthermore, some military and special equipment manufacturers also choose 535 aluminum castings for housings or structural components. This is because this material not only maintains stable performance in complex environments but also offers a good appearance and additional protective properties through surface treatments such as anodizing. For products requiring both durability and aesthetics, 535 offers a balance of strength, corrosion resistance, and surface treatment friendliness.

4.Is 535 a die casting alloy or is it used for sand casting (pouring)?

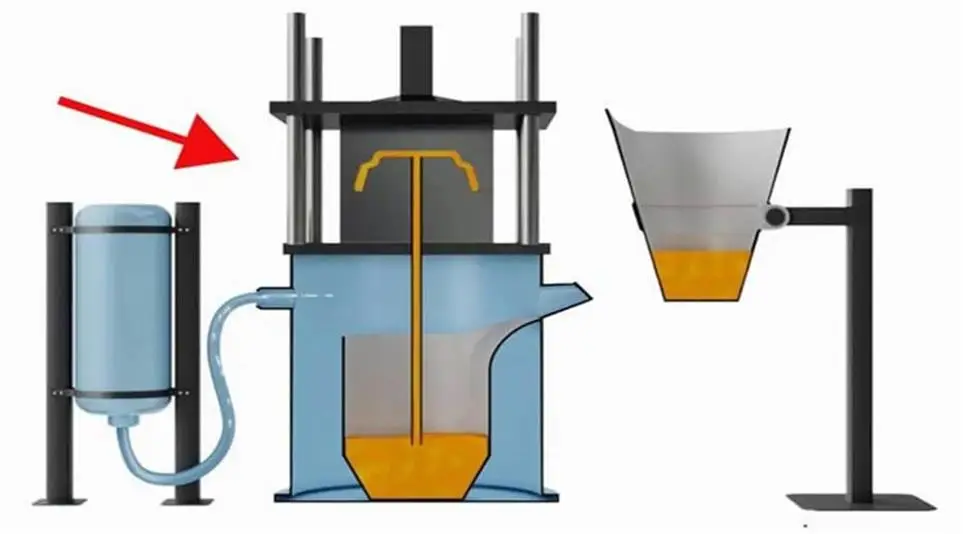

535 aluminum alloy is not a commonly used high-pressure die-casting alloy (common die-casting alloys are mainly A356, A380, and ADC12). In the industry, it is classified as a sand casting alloy. Most manufacturers and material handbooks list 535 under the “sand casting” category, which is also its most commonly used and most mature processing route. This is because 535 is a high-magnesium aluminum alloy. While it offers excellent corrosion resistance and dimensional stability, it is prone to problems such as mold sticking, hot cracking, and shrinkage cavitation in high-pressure die-casting environments. Its processing window is relatively narrow, and it lacks the stability of alloys specifically designed for die casting.

Another major advantage of sand casting is flexibility. Sand molds are well suited to the temperature control and feeding requirements of 535 during melting and filling. Through appropriate gating systems, risers, and venting methods, defect rates can be effectively reduced. Sand casting is also more suitable for manufacturing large or complex parts, which are typical applications for 535, such as marine equipment housings, instrument housings, and lightweight structural components.

For applications with higher dimensional accuracy and surface finish requirements, some manufacturers may also try low-pressure casting or permanent mold casting, but these processes require additional validation to ensure yield and stable performance.

5.What are the differences between 535 aluminum alloy and the more common A356 (or A380)?

Compared to A356 (a Si-based, heat-treatable alloy), 535 tends to have higher Mg and lower Si content, resulting in better corrosion resistance and anodized surface finishes. A356, on the other hand, offers greater versatility in casting fluidity, complex shape forming capabilities, and enhanced strength after heat treatment. It is widely used in die castings, gravity castings, and automotive structural parts. A380’s advantages lie in its excellent fluidity, strong mold filling capacity, and ease of high-pressure die casting in large quantities. Its balanced mechanical properties and workability make it suitable for thin-walled, complex structural parts.

In other words, if a part requires superior corrosion resistance and an aesthetically pleasing anodized surface, 535 is preferred. If higher strength or aging hardening are required, A356 offers greater flexibility. If the manufacturing process favors die casting and high-volume production, A380 is more suitable.

6.How does surface treatment (anodizing, spraying, powder coating) affect the surface finish of 535 aluminum castings?

535 aluminum alloy exhibits certain advantages in surface treatment. Due to its low silicon content, 535 achieves a relatively uniform surface finish after anodizing, often exhibiting a matte or satin white finish. Therefore, if anodizing is required to improve corrosion resistance or aesthetics, 535 is a well-suited material.

535 is also suitable for spray or powder coating, but the key lies in the pre-treatment process. To ensure coating adhesion, aluminum parts require routine pre-treatment steps such as degreasing and pickling. These steps remove surface grease, oxides, and impurities, ensuring uniform coating adhesion and enhancing durability.

Overall, 535 exhibits excellent adaptability to surface treatment. Whether anodizing, spraying, or powder coating, as long as standard pre-treatment procedures are followed for aluminum parts, ideal results can be achieved, while maintaining both aesthetics and corrosion resistance.

7.Summary

In summary, 535 aluminum alloy is a casting material that offers a balanced combination of corrosion resistance, workability, and dimensional stability. Choosing the right casting process, properly controlling the surface treatment process, and weighing the differences with other aluminum alloys based on application requirements can help achieve optimal casting performance and appearance. Whether in the marine, transportation, or precision instrument sectors, 535 aluminum alloy is a high-performance option worthy of consideration.

Improve the quality of your parts with LVXUN’s casting solutions.

Choosing LVXUN for aluminum alloy casting, you can get:

● Reliable quality assurance: We hold international certifications and strictly control casting quality.

● Flexible alloy and process options: We offer customized solutions for different applications.

● Complete processing services: We offer not only casting but also precision machining and a variety of surface treatments.

● Extensive project experience: We can efficiently complete everything from small-batch pilot production to large-scale production.

● Strong technical support: Our professional engineering team provides customers with material selection, design, and process consulting services.

FAQ:

Why do people use 535 alloy to cast aluminum parts?

By precisely controlling the magnesium content (6.5-7.5%), beryllium, and other elements, 535 aluminum alloy produces high-performance castings with excellent corrosion resistance and dimensional stability, making it ideal for demanding, performance-critical applications.

What are the weldability characteristics of 535 aluminum alloy?

Due to its high magnesium content, 535 aluminum alloy exhibits poor weldability. Welding can cause hot cracking and loss of strength, so it should be used with caution in applications requiring welding.

What are the mechanical properties of 535 aluminum alloy?

535 aluminum alloy exhibits high tensile and yield strength in the as-cast state, making it suitable for applications subject to significant mechanical stresses. This is why it is used in transportation and specialty equipment.

What do you think?

I’m impressed, I must say. Rarely do I come across a blog that’s

both equally educative and amusing, and without a doubt, you’ve hit the nail

on the head. The issue is an issue that not enough folks are speaking intelligently about.

I’m very happy I found this in my search for something concerning this.

Hello, just wanted to mention, I enjoyed this blog post.

It was funny. Keep on posting!

Great site you have here but I was wanting to know if you knew of

any message boards that cover the same topics discussed in this article?

I’d really love to be a part of group where I can get comments from other knowledgeable individuals that share the same interest.

If you have any suggestions, please let me know. Thanks!

I want to to thank you for this great read!!

I absolutely enjoyed every little bit of it. I have got you bookmarked to check out new stuff you post…

I just like the valuable information you supply on your articles.

I will bookmark your blog and take a look at once

more right here regularly. I am relatively sure I will be informed lots of new stuff

right right here! Good luck for the next!

That is really interesting, You’re an excessively skilled blogger.

I’ve joined your feed and look ahead to in quest of more of your fantastic post.

Also, I have shared your web site in my social networks

I am not certain where you are getting your info, but good

topic. I must spend some time studying more or understanding more.

Thanks for magnificent information I was on the lookout for this info for

my mission.

Stunning story there. What occurred after? Thanks!

Hurrah, that’s what I was seeking for, what a information! present here at this webpage, thanks admin of this web page.

This post gives clear idea in support of the new visitors of blogging, that genuinely how to do running a

blog.

Hello it’s me, I am also visiting this web site daily, this site is in fact fastidious and the

viewers are in fact sharing fastidious thoughts.

Hello, i think that i saw you visited my website thus i came

to return the desire?.I am attempting to in finding things to enhance my website!I suppose

its good enough to use a few of your ideas!!

I don’t even know how I ended up right here, but

I believed this submit was great. I don’t realize

who you are however certainly you are going to a famous blogger in the

event you aren’t already. Cheers!

This is my first time pay a quick visit at here and i am actually impressed to read all at single place.