Casting and Forging: Differences and Choices

Metal products are widely used in modern industry and everyday life, from mechanical parts and pipes and valves to building structures and industrial equipment.

Manufacturing these metal parts and products involves a variety of processes, including cutting, bending, welding, machining, stamping, casting, and forging.

However, among the many metal forming methods, only casting and forging can internally alter the metal’s shape, enabling deeper structural adjustments and performance optimization.

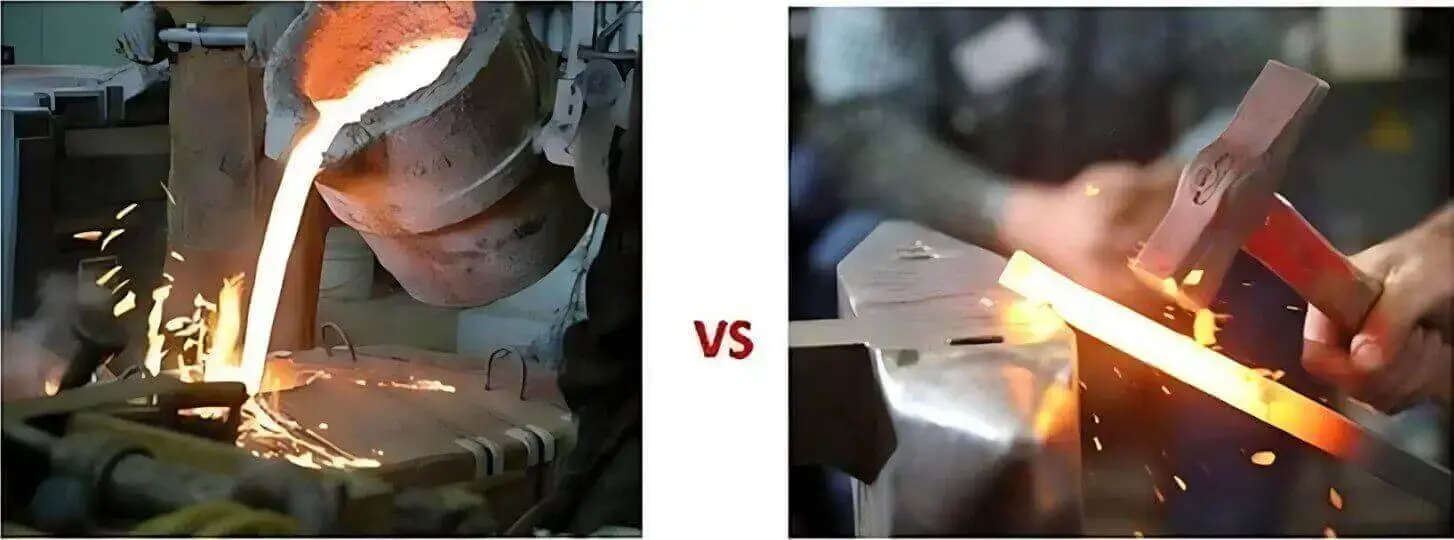

● Casting heats the metal until it melts, pours it into a mold, and then cools and solidifies it into the desired shape.

● Forging, on the other hand, modifies the metal’s shape while it is still in the solid state through the combined action of thermal and mechanical energy.

These two methods differ significantly in their principles, finished product properties, and applications. As an industrial manufacturing and engineering company specializing in metal forming and processing, we will explore in depth the differences between casting and forging, their respective advantages, and applicable industries, providing practical guidance for selecting the appropriate process.

Table of Contents

The Advantages of Casting and Forging

What is Casting?

Casting is a manufacturing process in which metal is heated to a molten state, poured into a prefabricated mold, and then removed from the mold after cooling and solidification. It is suitable for mass production, as the same mold can be used to repeatedly produce parts with identical shapes.

The advantages of casting include:

There is virtually no upper limit to the weight of castings, allowing production of parts ranging from small parts to very large components.

The material range is wide, allowing for the use of nearly any metal and alloy.

The addition of elements such as chromium, nickel, and molybdenum to the liquid metal facilitates the preparation of specialized alloys, which is more difficult to achieve with forging.

The mold manufacturing cost is relatively low.

It is suitable for medium to large-scale production.

It can easily produce parts with complex structures and precise details.

What is Forging?

Forging is a process in which metal is shaped by applying pressure (using a hammer or die) while in its solid state. During the forging process, the metal undergoes plastic deformation and continuous grain flow, which increases overall strength and effectively eliminates internal defects such as porosity and inclusions.

The advantages of forging include:

Production results in excellent mechanical properties and higher strength than most other machining methods.

Outstanding impact resistance allows for greater impact load resistance than comparable castings.

Product quality is more consistent because there are no porosity, shrinkage, cavities, or cold shuts common in casting.

Dense grain structure provides high mechanical strength, requiring less precious metal alloying to meet strength requirements.

The fine grain structure imparts excellent wear resistance, allowing even lower-hardness forgings to achieve wear resistance similar to that of harder castings, while offering improved impact resistance.

Process Classification of Casting and Forging

As a professional metal forming and fabrication manufacturer, I will now categorize casting and forging processes based on over 15 years of experience.

What processes does casting involve?

Casting processes can be divided into three main categories based on how the mold is used and the characteristics of the forming process:

Permanent Mold Casting

Permanent mold casting utilizes reusable metal molds (typically made of cast iron, steel, or graphite). It is suitable for mass production of metal parts with stable dimensions and consistent properties. Main types include:

Gravity Mold Casting: This relies on the metal’s own gravity to fill the mold. This process is simple and cost-effective, making it suitable for medium- to large-volume production of aluminum, magnesium, and copper alloys.

Slush Mold Casting: This is used to produce lightweight, hollow parts. Forming is achieved by controlling the thickness of the solidified metal in the mold. It is suitable for decorative and non-load-bearing parts.

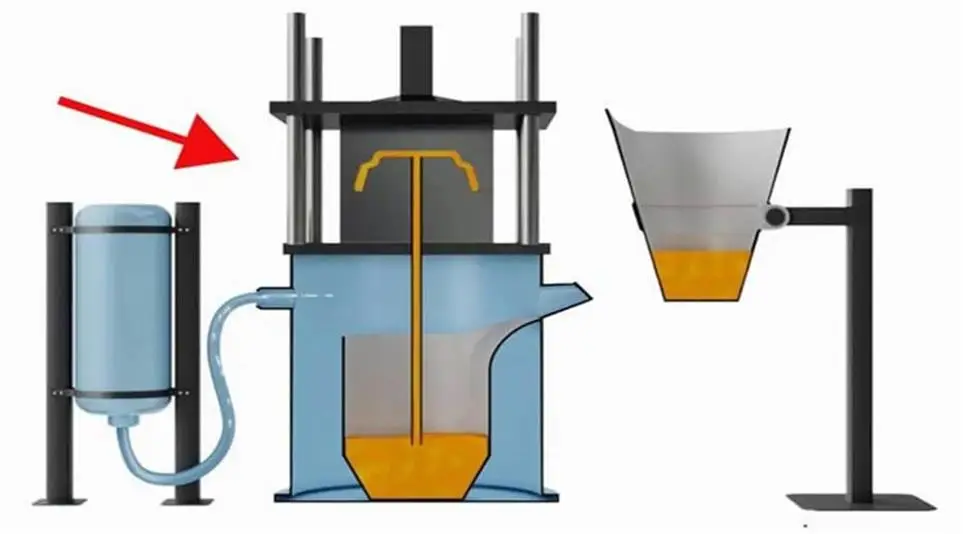

Low-Pressure Mold Casting: This utilizes low air pressure to push metal upward into the mold cavity from below, reducing inclusions and porosity. It is suitable for complex shapes, thin walls, and high-performance aluminum alloy parts.

Vacuum-Assisted Mold Casting: This creates a vacuum in the mold cavity to draw metal in, reducing porosity and increasing density. It is suitable for parts requiring precision and high strength, such as aerospace and medical equipment components.

Expendable Mold Casting:

Expendable molds are destroyed during the molding process and are suitable for the flexible production of various part shapes. Main types include:

Sand Casting: This is the most common process, low-cost, and suitable for large sizes and high-temperature-resistant metals, but can result in a rougher surface.

Shell casting: Uses resin-coated sand to form a thin shell, offering superior precision and surface quality compared to sand casting.

Investment casting: Also known as lost wax casting, offers high precision and a smooth surface, suitable for complex, high-performance alloy parts.

Gypsum casting: Offers excellent surface replication and high precision, but is unsuitable for metals with high melting points.

Lost foam casting: The mold is made of foam plastic, which vaporizes directly during pouring to form the cavity, making it suitable for producing parts with complex, integral structures.

Other casting processes

In addition to the two aforementioned methods, there are also some casting methods with specialized applications:

Die casting: Uses high pressure to rapidly fill the mold with metal, offering high production efficiency and suitable for mass production of complex, high-dimensional precision non-ferrous metal parts.

Centrifugal casting: Uses centrifugal force to evenly distribute metal on the mold wall, commonly used in the production of pipes, rings, and other products.

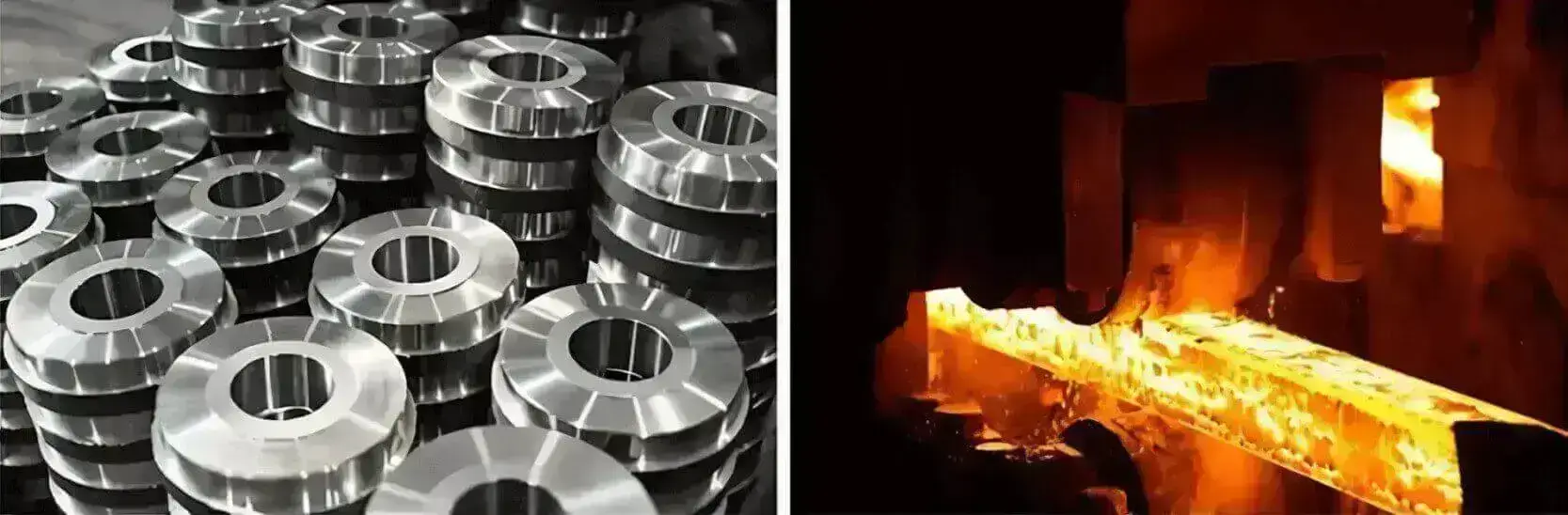

Continuous casting: Used for the continuous production of metal profiles, widely used in metallurgical industries such as steel and aluminum.

LVXUN‘s Metal Casting Services

What processes are involved in forging?

Forging processes can be primarily categorized by temperature, forming method, and material.

By Temperature:

Hot forging: Performed when the metal is above its recrystallization temperature, it exhibits excellent plasticity and low deformation resistance, making it suitable for manufacturing large or complex parts.

Warm forging: Performed when the metal is below its recrystallization temperature but above room temperature, this reduces forming forces and minimizes oxidation and work hardening after deformation.

Cold forging: Performed at room temperature, it offers high dimensional accuracy and good surface quality, but requires high forming forces.

By Process:

Open Die Forging (Free Forging): The metal billet is formed between a flat anvil or simple tool, suitable for producing large parts or small batches.

Closed Die Forging (Die Forging): The metal is formed within the die cavity, offering high dimensional accuracy and high production efficiency, making it suitable for mass production.

By Material:

Steel Forging: Made of carbon steel or alloy steel, it is widely used in machinery, automotive, and aviation industries.

Aluminum Forging: Lightweight and corrosion-resistant, it is commonly used in lightweight aerospace and automotive parts.

Forged brass and bronze: They offer excellent wear and corrosion resistance and are often used for pipe fittings, valves, and decorative components.

Specific Differences Between Casting and Forging

Combining the two sections above, we can conclude that castings are made by melting, pouring, and solidifying, while forgings are formed by physical forces while the metal remains in a solid state. Therefore, the final products produced by these two processes have distinctly different properties.

When deciding which process is best for your project, it’s important to identify your priorities: Do you require a complex shape? Does it require large dimensions? Does it require high strength? The chart below provides the most common considerations when choosing between casting and forging.

| Selection Factors | Metal Forging | Metal Casting |

| Structural Integrity | High strength, stable material properties | Higher porosity, prone to defects |

| Geometric Complexity | Not suitable for complex geometries | Supports high complexity and tight tolerances |

| Product Size | Size and thickness limited; larger sizes harder to process | Compatible with various sizes |

| Material Selection | Limited alloy types | Suitable for almost all metal materials |

| Secondary Processing | Mainly for adjusting dimensions and optimizing surfaces, with small processing volume | In addition to dimension adjustment, often requires detection and handling of potential defects |

| Cost | More economical for medium and large-scale production | Usually lower than forging, depending on specific processes |

If you’ve reviewed the chart and still aren’t sure which process to choose, don’t worry; there’s a detailed explanation below.

The specific differences between casting and forging are primarily reflected in the following aspects:

Forming Method

Casting involves heating metal to a molten state, pouring it into a mold, and then cooling and solidifying it. Forging involves changing the metal’s shape through mechanical forces such as pressing, hammering, or extrusion while the metal remains in a solid state.

Grain Structure and Strength

Forging stretches the metal’s grains during the forming process, aligning them in a specific direction and maintaining continuity. This increases the metal’s strength and toughness, making it more impact-resistant and less prone to shattering. Casting, on the other hand, disrupts the original grain flow, resulting in random grain orientation after solidification, resulting in relatively lower overall strength and toughness.

Size and Shape Limitations

Casting has virtually no size limitations and can produce extremely large parts (even exceeding 100 tons) with complex shapes. Forging is limited by equipment capacity and metal plasticity, making it difficult to process extremely large or complex geometric parts.

Material and Alloy Selection

Forging raw materials are typically standard steel billets or alloys provided by the steel mill, limiting the selection. Casting allows for in-house melting at the foundry, allowing for greater flexibility in the use of specialized alloys and reducing production costs.

Internal Quality and Strength Distribution

Forgings offer higher strength and fatigue life in specific directions, making them particularly suitable for parts subject to impact and high loads. Castings have a more uniform strength distribution and are suitable for parts requiring consistent overall performance.

Cost and Production Efficiency

Casting offers high mold utilization and minimal machining allowances for producing complex parts, resulting in relatively low costs. Forging, however, requires high energy and equipment, and is generally more expensive than casting, but the finished product offers superior performance.

Application Scenarios

Casting is suitable for low-cost, large-scale, complex parts, or parts using exotic alloys, such as pump bodies, housings, and mechanical components. Forging is suitable for parts requiring high strength, toughness, and reliability, such as crankshafts and gears.

Which is better, casting or forging?

In summary, casting is often the lower-cost and more versatile option, while forging offers higher strength and wear resistance. The best process depends on your project’s priorities. If low cost, exotic alloys, and complex geometries are your top priorities, casting may be the best choice. However, if strength and structural integrity are key, forging may be a better option.

Discuss your casting or forging needs with LVXUN

With LVXUN, you no longer have to worry about choosing between casting and forging. Our technical team will provide you with the most suitable metalworking process to produce the products you need. Whether your part is complex and requires high-volume production, requires increased durability, or even requires post-processing machining and surface treatment, our manufacturing services can meet your needs.

Ready to start your casting or forging project? Contact us today.