Defense Investment Castings: Products, Materials, and Quality Control

Defense investment casting requires far greater technical expertise and process control than conventional industrial casting, which is precisely what sets us apart. For years, LVXUN has specialized in providing investment castings made of complex structures and high-performance alloys for defense projects, accumulating extensive industry experience and process knowledge.

Our core strengths include castability assessments for complex parts, high-precision CNC post-machining, and a comprehensive quality traceability system. This ensures that every product we produce meets or exceeds international standards.

Table of Contents

1.What is defense investment casting? How does it differ from conventional investment casting?

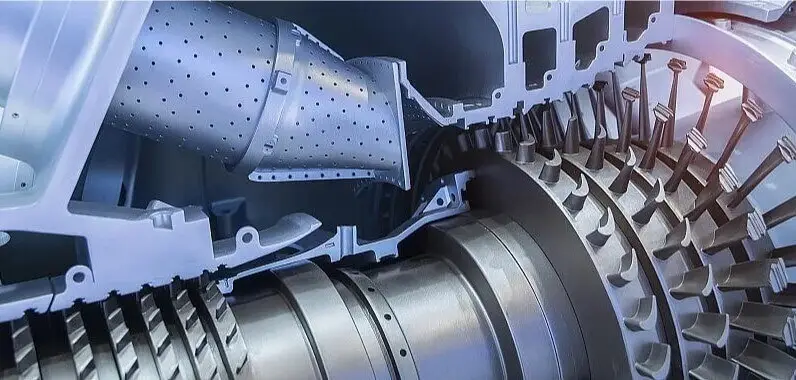

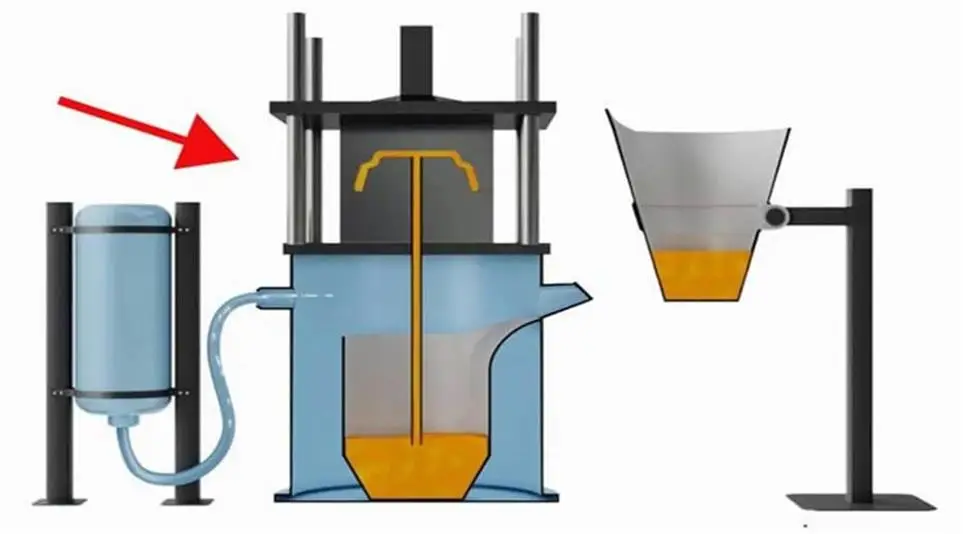

Defense investment casting is essentially a higher-standard investment casting process, primarily used to manufacture complex, high-precision parts for the military, such as aircraft engine blades, radar system brackets, and structural components for high-temperature environments. Its basic process is similar to conventional investment casting, following the same “wax pattern – shell mold – melting – pouring – shelling” process, but with more stringent requirements in many key details.

First, higher precision is achieved. Dimensional tolerances generally reach CT5 to CT7, and geometric consistency requirements are also stringent. Second, stricter material control is required. For materials like titanium alloys and nickel-based alloys, the source and composition of raw materials must be traceable.

The production process must comply with military quality systems such as AS9100 and NADCAP, with detailed specifications for molds, temperature control, shell molds, and other processes. Furthermore, each part undergoes non-destructive testing and heat treatment verification, such as X-ray, ultrasonic, and penetrant testing.

Finally, a comprehensive traceability system is in place, ensuring long-term, reliable operation of parts in complex environments.

Simply put, defense investment casting is not just about achieving higher precision; it’s also a comprehensive, high-standard manufacturing system.

2.What products or components are often referred to as defense investment castings?

Defense investment casting is primarily used to manufacture structural parts with complex shapes, precise dimensions, and demanding operating environments. These parts are commonly used in defense equipment, including aircraft propulsion systems, electronic systems, and structural support systems. Typical components include:

High-temperature alloy turbine blades, guide vanes, and turbine disks for aircraft engines;

Combustion chamber casings, duct connections, and cooling duct structures in airborne power systems;

Brackets, covers, and seals for navigation systems;

Infrared and radar equipment housings and high-frequency electromagnetic shielding components;

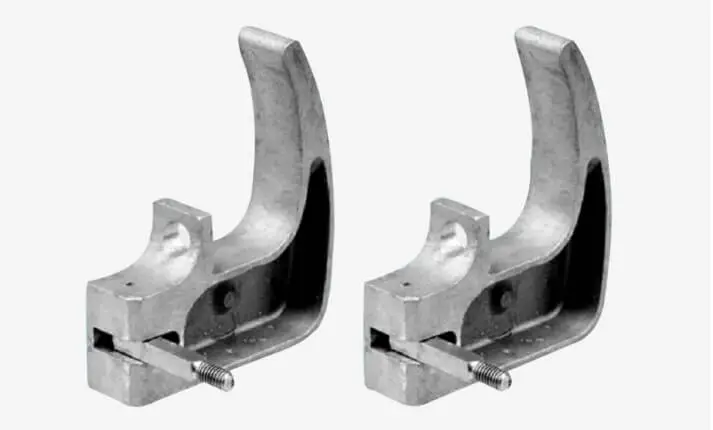

Precision hinges, tail fin connectors, and control mechanism housings in aerodynamic control structures;

Load-bearing connectors and thermal protection components in special vehicles and equipment.

Because these parts often feature thin walls, complex internal cavities, and tight tolerances, investment casting is the preferred process for their formation.

LVXUN Casting, as a professional defense casting manufacturer, consistently utilizes top-tier processes and premium materials to provide high-quality, high-volume casting solutions for numerous critical military and defense projects. We ensure that every product complies 100% with national standards and industry specifications. The following are some of the products we manufacture using the investment casting process:

Turbine blades

Guide vanes

Turbine discs

Combustion chamber casings

Cooling ducts

Navigation brackets

Electromechanical housings

Electromagnetic shields

Seal assemblies

Control mechanism housings

Embrane connectors

Heat shields

Bearings

Bolt catches

Bolt carriers

Canards

High-temperature valves

Bipod head

3.What are the special material requirements for defense investment casting?

Defense investment castings place extremely high demands on materials. Because these parts must operate for long periods of time in high-temperature, high-pressure, highly corrosive, or vibrating environments, the material selection must be impeccable. The following are some commonly used materials and their typical applications:

Nickel-based superalloys

This material is particularly suitable for high-temperature parts in aircraft engines, such as turbine guide vanes, combustion chamber casings, and nozzle segments. It can maintain strength and stability at temperatures exceeding 1,000 degrees Celsius.

Titanium alloys

Titanium alloys are lightweight, strong, and corrosion-resistant. They are commonly used in flight control system connectors, navigation brackets, and empennage connectors, where weight is a concern.

Stainless Steel

Stainless steel is suitable for use in medium-temperature and humid environments, such as shipboard electronic equipment, radar brackets, and transmission components. It offers excellent strength and corrosion resistance.

Low-Alloy Steel

It has high strength and impact resistance, making it suitable for heavy-duty structural parts, such as armored vehicle joints, steering systems, and track supports.

Low Carbon Steel

It is inexpensive and easy to process, and is often used for less critical parts, such as brackets, fasteners, and in-cabin mountings. Surface treatment is typically used to prevent corrosion.

Cobalt-Based Alloys

It is suitable for high-temperature friction applications, such as seals, bushings, and nozzle adjustment rails. It is wear-resistant, corrosion-resistant, and stable even at high temperatures.

Copper-Based Alloys

It has excellent electrical and thermal conductivity and is commonly used in electronic module conductive parts, heat sinks, and electromagnetic shielding housings. Beryllium bronze and tin bronze are more commonly used.

Aluminum Alloys

It is lightweight and easily formed, making it suitable for airborne equipment housings, navigation device baseplates, control module brackets, and other applications, contributing to weight reduction.

These materials undergo rigorous testing before use, including component analysis, strength testing, and microstructure inspection, to ensure stability and reliability, meeting the high-precision, high-strength parts required for defense equipment.

4.Why does the defense industry use investment casting over forging or machining?

The defense industry chooses investment casting primarily because it offers unmatched advantages over other processes for manufacturing complex parts. The defense industry chooses investment casting primarily because it offers unmatched advantages over other processes for manufacturing complex parts. You can learn more about our casting processes in our media library.

First, investment casting can achieve near-net-shape shapes, meaning the casting dimensions are very close to the design requirements, requiring minimal machining. This significantly reduces waste and saves costs for precious materials like titanium alloys and high-temperature alloys.

Second, investment casting is well-suited for manufacturing complex parts, such as turbine blades with internal cooling channels, thin-walled structures, or specialized cavities—designs that are difficult or prohibitively expensive to achieve using traditional forging or machining.

Furthermore, by properly controlling the cooling rate and shell structure during the casting process, investment casting ensures a uniform and dense internal structure, enhancing strength and durability—particularly important for defense equipment.

Finally, defense manufacturing often requires small batches and high-variety production. Investment casting offers relatively low mold costs, flexible processes, and the ability to quickly meet diverse needs with a fast response time. In contrast, forging molds are expensive and require extensive machining, making them less suitable for these applications.However, subsequent finishing work can be performed by CNC machining technology.

5.What are the quality control systems for defense investment casting?

Quality control is a core component of the defense investment casting system, ensuring that every casting meets stringent requirements for shape, size, structural integrity, and material properties. LVXUN’s primary quality control measures include:

Material Source Management: Raw materials must be certified for material quality, ensuring traceability of chemical composition and smelting batches.

Process Control: This includes stability management of key parameters such as dewaxing temperature, mold drying and humidity, pouring temperature, and cooling rate.

Non-destructive Testing: After casting, castings undergo non-destructive testing using X-ray, ultrasonic, and magnetic particle techniques to eliminate defects such as internal porosity and cracks.

Metallographic and Mechanical Testing: Representative specimens are tested for grain size, microstructure, hardness, tensile strength, and impact strength.

Heat Treatment Process Control: Process steps such as solution treatment and aging treatment ensure that castings meet performance standards.

Certification Systems: We are certified to quality systems such as AS9100 and NADCAP, and implement process documentation and product traceability throughout the entire production chain.

6.LVXUN’s Advantages in Precision Military and Defense Investment Castings

In the military and defense sector, choosing a trustworthy investment casting partner is crucial. With a mature engineering system, advanced machining capabilities, and extensive industry experience, we provide customers with metal casting solutions with superior performance and consistent quality. Our strengths are:

Engineering-driven, focused on the entire metal investment casting process;

Customized designs and in-house mold development tailored to project requirements;

Experienced in casting complex geometries and difficult-to-machine parts;

Supporting high-volume investment casting production with strong delivery capabilities;

A wide range of materials, including ferrous metals and non-ferrous alloys;

Extremely narrow parting lines, eliminating the need for additional flash trimming;

In-house CNC precision machining equipment ensures machining efficiency and accuracy;

Providing one-stop services from investment casting to post-processing;

Strong quality control ensures consistency and reliability in mass production;

Our team of experienced engineers, casting engineers, and machining engineers provides you with truly reliable technical support. This comprehensive strength is difficult to find with other suppliers. Choosing LVXUN Casting ensures not only the best quality but also competitive pricing.