Low Pressure Casting – Principles, Process, Equipment, and Applications

Low pressure casting uses low pressure to slowly push molten metal into a mold, allowing it to take shape under stable conditions. Compared to traditional methods, it reduces defects such as porosity and slag inclusions, resulting in finished products with higher precision and strength. It is often used in industries with extremely high quality requirements, such as the automotive and aerospace industries.

This article contains everything you need to know about low pressure casting. If you need more detailed information after reading this article, please contact our professional engineers.

Table of Contents

1.What is Low Pressure Casting?

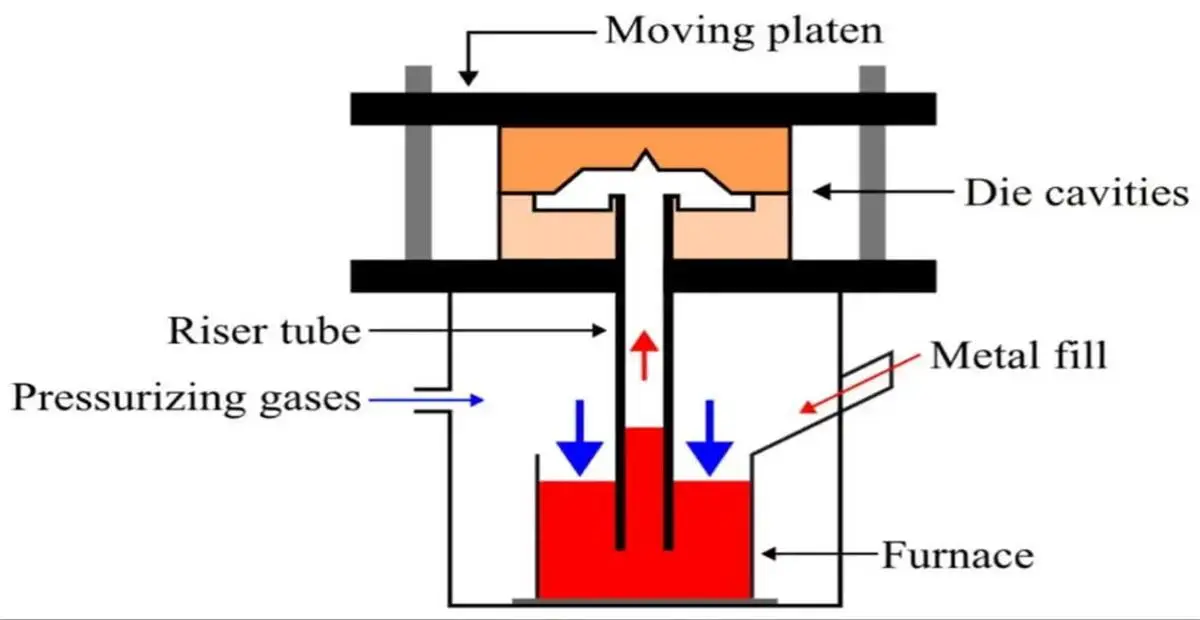

Low pressure casting is a process in which molten metal is steadily poured from the bottom of a sealed crucible through a riser tube into the mold cavity using low gas pressure, where it solidifies and forms in a controlled environment. The entire process ensures uniform and stable filling, avoiding turbulence, splashing, and secondary oxidation.

This process allows for continuous replenishment of molten metal during the solidification shrinkage phase, significantly improving the density and dimensional accuracy of the casting and reducing defects such as porosity and shrinkage. In addition, a cooling system is typically installed within the mold to precisely control the solidification rate and temperature distribution, further enhancing the microstructure and mechanical properties of the casting.

Due to its high precision, high density, and excellent overall performance, low pressure casting is widely used in high-end manufacturing applications such as automotive parts, aerospace structures, energy equipment, and precision machinery, making it a key method in modern metal forming.

2.History of Low Pressure Casting

Low pressure casting originated in the early 20th century. In 1906, the Wetherill brothers in the United States patented low-pressure metal mold casting equipment. Around 1910, Queneau in Germany explored its application in aluminum bronze and manganese bronze. At the same time, Lake in the United Kingdom also patented equipment for lead-tin alloys. In 1917, France developed a low pressure casting machine utilizing steam pressure, but its early industrial applications were limited.

After World War II, E.C. Lewis of British Aluminum promoted technological advancements and successfully produced light alloy beer kegs in 1950. Since the 1960s, low pressure casting has been widely used in the UK, US, Japan, and Germany, achieving particular breakthroughs in aluminum alloy wheel manufacturing and subsequently developing into a significant modern casting process.

3.How does low pressure casting work?

The principle of low pressure casting is to use controlled low pressure to steadily push molten metal from the bottom of the mold into the die cavity, ensuring uniform filling and dense solidification. Low pressure, typically between 20 and 100 kPa, ensures smooth metal flow without turbulence, thereby reducing porosity and inclusions.

The metal fills the mold from the bottom up, with air vented through the top vent. Meanwhile, constant pressure continues during solidification, ensuring the metal densely fills the mold details and minimizing shrinkage cavities and other defects.

The molten metal is kept high before entering the mold to prevent premature solidification. After the pressure is released, it can be recycled back into the holding furnace. By controlling pressure, temperature, and exhaust, low pressure casting can produce high-precision, high-density castings with complex shapes.

4.What is the process flow of low pressure casting?

The low pressure casting process primarily involves the following steps:

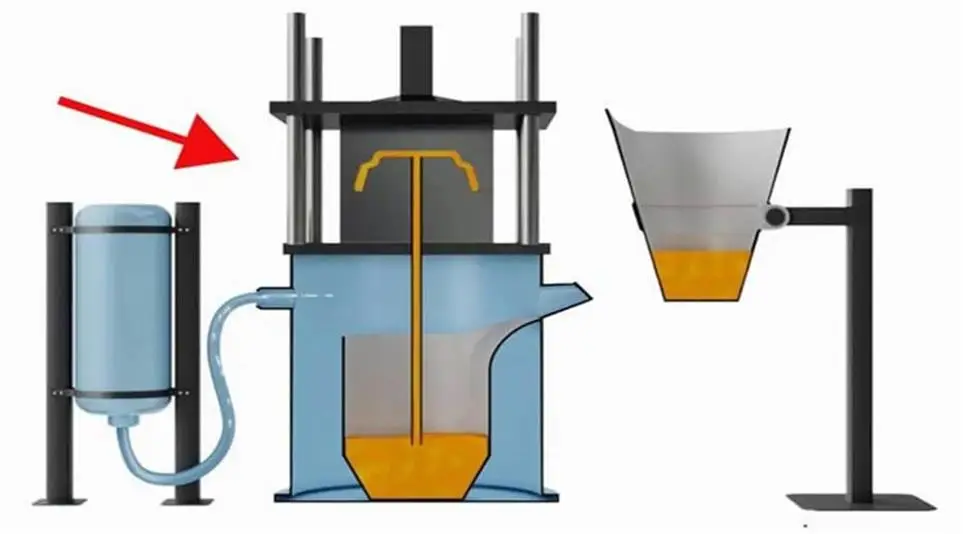

First, the desired metal alloy is melted in a furnace and heated to the appropriate casting temperature. Different alloys have different melting points, so the temperature must be determined based on the alloy’s composition to ensure the metal is completely melted and ready for casting.

Once the molten metal reaches the appropriate temperature, it is transferred to a holding furnace beneath the mold to maintain a stable temperature and ensure a continuous supply of metal during the casting process.

Next, the molten metal is pushed into the mold through a riser tube using low pressure. This pressure, typically between 20 and 100 kPa, allows the metal to fill the mold cavity smoothly and controllably from the bottom, while air is expelled through a top vent, reducing porosity and inclusions.

Once the metal enters the mold, it begins solidifying under constant pressure. Maintaining pressure during the solidification phase allows the metal to fill mold details as it cools and contracts, resulting in a dense, uniform internal structure.

Once the metal has fully solidified, the pressure is released, and the remaining molten metal is recycled back into the holding furnace to minimize material waste.

After the mold cools to the desired temperature, it is opened and the casting is removed. Depending on the part’s requirements, trimming and finishing may be required to remove excess burrs and meet quality standards. Various testing equipment is also required to ensure casting quality control.

The entire process includes mold preparation, molten metal injection, constant pressure solidification, pressure release and metal recovery, cooling and removal, and trimming and finishing. Each step is closely coordinated to ensure high casting precision, uniform internal structure, and minimal defects.

5.Main Components of Low Pressure Casting Equipment

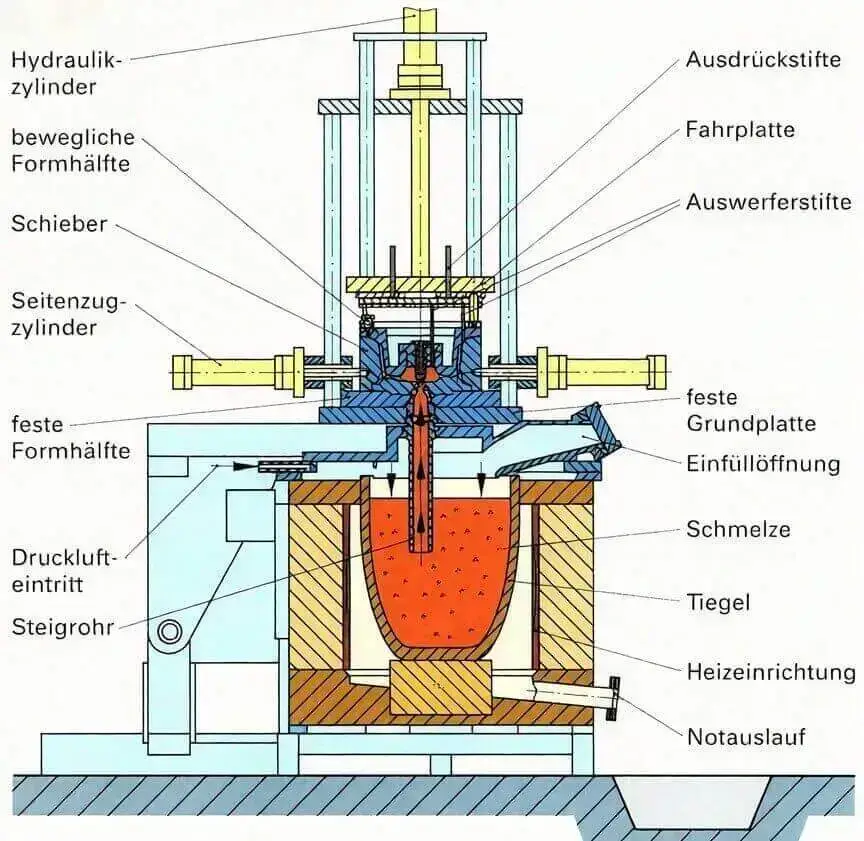

The core equipment of low pressure casting is the low pressure casting machine, but the entire system also includes a variety of key components and auxiliary equipment, including:

Low Pressure Casting Machine:

This is the main equipment in the low pressure casting process, used to control the filling and solidification of the molten metal. It typically includes a main unit, hydraulic system, and electrical control system, and is the core of the entire system.

Holding Furnace/Heating Furnace:

This is used to melt, store, and hold the molten metal to ensure it maintains the appropriate temperature and good fluidity during the casting process.

Riser:

Connects the holding furnace to the mold and is used to transport molten metal upwards into the mold cavity. Its material and dimensions must be precisely designed based on the type and size of the casting.

Mold:

Used to shape the casting, it is typically made of high-strength material and contains internal structures such as cooling channels, exhaust ports, and feed ports. The mold design directly affects metal fluidity, solidification shrinkage, and casting quality.

Low pressure injection system:

This is the core component of low pressure casting equipment. Its primary function is to force molten metal into the mold using low pressure. This system typically consists of a gas compressor, cylinder, and pressure regulating valve. The low pressure generated by the gas compressor forces the metal through the injection tube into the mold.

Cooling system:

Comprising cooling water pipes, a water pump, or other cooling medium channels, it is used to uniformly cool the mold and accelerate metal solidification, thereby preventing casting deformation and thermal stress.

Exhaust system:

During the low pressure casting process, air or gas within the mold cavity must be exhausted to prevent the formation of pores and casting defects. The exhaust system ensures the smooth escape of gases by designing exhaust channels within the mold.

Ejector System:

The ejector system is used to eject the cooled and solidified casting from the mold. It typically includes ejector pins and pneumatic or hydraulic actuators. This system must operate smoothly and reliably to prevent damage to the casting and ensure smooth ejection from the mold.

Alloy Treatment Equipment:

These include rotary degassers and stationary deslagging machines, used to degas and remove slag from the molten metal, improving the mechanical properties and surface quality of the casting.

Deslagging Equipment:

This removes slag and oxides from the surface of the molten metal before pouring. Manual or automated equipment can be used.

Testing and Measuring Equipment:

These include thermometers, pressure gauges, and spectrometers, used to monitor key parameters such as temperature, pressure, and metal composition in real time to ensure process stability.

Control Systems:

Modern low pressure casting equipment is often equipped with PLC or computer numerical control systems (CNCs) to automatically monitor and adjust process parameters such as temperature, pressure, and time, improving production efficiency and stability.

6.What metals are commonly used in low pressure casting?

Aluminum

Aluminum alloys are the most widely used materials in low pressure casting. Their excellent fluidity allows them to effectively fill intricate mold details, making them particularly suitable for producing thin-walled and complex-shaped castings. Aluminum is lightweight, yet possesses high strength and corrosion resistance. It is widely used in automotive engine parts, aerospace structural components, and consumer electronics housings.

Magnesium

Magnesium alloys are known for their lightweight and high strength-to-weight ratio. Their excellent fluidity allows for smooth forming at low pressures and reduces porosity. In automotive and aerospace manufacturing, magnesium is commonly used in transmission housings, steering wheels, and cabin components, helping to reduce weight and improve efficiency.

Copper

Copper alloys are less commonly used in low pressure casting than aluminum and magnesium due to their high melting point and relatively poor fluidity. However, their excellent electrical and thermal conductivity make them suitable for the electronics and electrical industries, such as heat sinks and connectors. However, specialized mold design and anti-oxidation measures are required to ensure casting quality.

Zinc

Zinc alloys have a low melting point, good fluidity, and can solidify quickly while maintaining dimensional stability, making them suitable for producing small, complex-shaped parts. It causes less wear on the mold and has high production efficiency. It is often used in hardware, decorative accessories and wear-resistant parts, such as door handles and decorative parts.

7.Advantages and Disadvantages of Low Pressure Casting

(1) Advantages of Low Pressure Casting

High Dimensional Accuracy

Maintaining low pressure during the solidification process allows the metal to continuously compensate for shrinkage, reducing shrinkage defects, thereby obtaining high-precision and consistent castings. This feature is particularly suitable for manufacturing parts such as automobile wheels that have strict requirements on symmetry and size.

High purity of castings

The molten metal fills the mold from bottom to top, preventing surface slag from entering the mold cavity. At the same time, the stable filling process reduces splashing and rolling, and reduces the formation of oxides and inclusions, so the purity and quality of the casting are higher.

Good formability

The liquid metal rises steadily under low pressure and has strong fluidity. It can form parts with clear contours and smooth surfaces, which is suitable for manufacturing products with complex geometric shapes.

Dense structure and excellent performance

The metal solidifies under pressure, with fine grains and a compact internal structure, which significantly improves the mechanical properties and strength of the casting.

High material utilization rate

The filling process is controllable, which reduces the scrap rate. At the same time, the unused molten metal can flow back to the holding furnace to reduce material waste.

Wide application range

It can be used for a variety of non-ferrous alloys, such as aluminum, magnesium, zinc, etc., to meet the application needs of different industries.

Reusable Molds

Low-pressure casting is a permanent mold casting method. The mold is reusable and uses low-pressure filling to produce high-quality castings.

(2) Disadvantages of low pressure casting

Low production efficiency

Since the filling relies on low pressure, the casting cycle is long and the production cycle is slow, which is not suitable for large-scale high-speed production.

High equipment and maintenance costs

The process requires special equipment and a large initial investment. In addition, long-term contact between molten metal and equipment components may cause corrosion and erosion, increasing maintenance costs.

Wall thickness limit

The minimum wall thickness of low pressure casting parts is usually around 3 mm, which makes it difficult to manufacture extremely thin-walled precision parts. In this respect, it is not as good as high-pressure die casting process.

Relatively high energy consumption

Although low pressure casting is more energy-efficient than high-pressure die casting and sand casting in some links, the overall energy consumption is still higher than simpler methods such as gravity casting.

Highly demanding on operation

The process requires strict control of molten metal temperature and mold filling pressure, requiring trained operators; otherwise, casting quality can be compromised.

8.Applications of Low Pressure Casting

Automotive Industry:

Aluminum alloy wheels, engine blocks, cylinder heads, suspension components, manifolds, transmission housings

Aerospace:

Engine blades, turbine components, lightweight structural parts, key aerospace castings

Electronics and Electrical:

Radiator housings, motor housings, electronic component housings

Industrial Machinery:

Pump casings, impellers, housings, and other parts

Consumer Products:

Golf club heads, tennis rackets, bicycle frames, kitchenware, and furniture components

Household Appliances:

Washing machine parts, vacuum cleaner parts, and cooking equipment parts

LVXUN: Your Low Pressure Casting Partner

Choosing us as your low pressure casting partner means you receive a one-stop solution from design to mass production. We not only master the mature low pressure casting process, ensuring high precision, high purity, and reliable material properties for castings, but also have an experienced engineering team that can provide process optimization and design advice from the very beginning of your project, helping you mitigate risks and reduce costs.

Our strength lies not only in low pressure casting itself, but also in our comprehensive supporting manufacturing capabilities—CNC machining, 3D printing, surface treatment, and other services—all performed in one facility, ensuring efficient collaboration and rapid delivery.

Whether it’s complex components for industries like automotive, aerospace, or consumer electronics, we can provide customized solutions tailored to your needs. You can request an instant quote by uploading your design files.

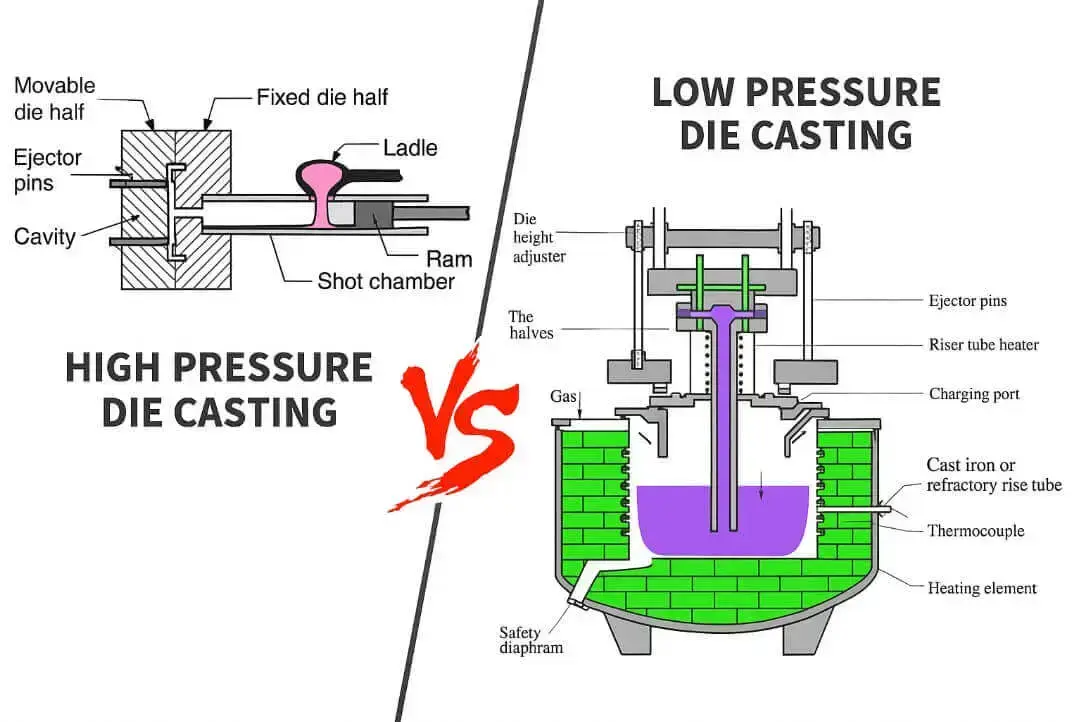

Low Pressure Casting vs High Pressure Casting

Low pressure casting and high-pressure casting each serve different applications, and the choice often depends on part complexity, production volume, and manufacturing costs. Below, we systematically compare the two processes across thirteen dimensions. It’s no exaggeration to say this is the most comprehensive low pressure casting vs high pressure casting comparison you’ll ever see. After reading this, you’ll be able to more clearly determine which process is best for producing your part.

| Comparison Item | Low Pressure Die Casting | High Pressure Die Casting |

| Pressure Characteristics | Pressure is relatively low, generally less than 0.08MPa, and can reach about 0.15MPa in special cases. | Pressure is relatively high, can reach several hundred MPa. |

| Metal Liquid Flow Velocity | The flow velocity of the metal liquid is relatively low, generally 150mm/s under pouring state, and the scouring of the cavity is small. | The metal liquid flows fast in the cavity, can reach 60m/s, and can be as high as about 120m/s. The scouring of the cavity is large. |

| Applicable Cavity Materials | The cavity can be metal mold, sand mold, or other material molds (relatively low requirements for cavity materials). | The cavity can only be metal mold (relatively high requirements for cavity materials). |

| Complexity of Castings That Can Be Produced | Can produce castings with relatively complex cavities. | Currently, technology can only produce castings with relatively simple cavities. |

| Size of Castings That Can Be Produced | Can produce small, medium and large castings. | Usually produces small and medium-sized castings. |

| Thickness of Castings That Can Be Produced | Suitable for thick-walled parts (not suitable for thin-walled parts less than 3mm). | Can produce thin-walled parts (thickness less than 0.4mm). |

| Casting Quality | No pores inside the casting. | There may be pores inside the casting, and special processes need to be adopted for parts with airtightness requirements. |

| Casting Strength | The part strength is high, and the solidification process lasts for a long time under constant pressure, resulting in a dense structure. | The part strength is good, but it is not as good as that of low-pressure die casting due to high pressure and short time. |

| Heat Treatment Feasibility | The casting can be strengthened by heat treatment. | Cannot be fully strengthened by heat treatment or cannot be heat-treated at all. |

| Surface Smoothness | The surface smoothness of the casting is general. | The surface of the casting is smooth. |

| Casting Cycle | The casting cycle is relatively long, and the production speed is general. | The casting cycle is relatively short, and the production speed is relatively fast. |

| Process Yield Rate | Process yield rate is 80-95%. | Process yield rate is 70-90%. |

| Operating Cost and Applicable Order Quantity | The operating cost is relatively low, more suitable for situations where the quantity is not very large. | The startup operating cost is relatively high, more suitable for mass order production. |

FAQ:

What are the applications of low pressure casting?

Low pressure casting is commonly used to manufacture complex, high-quality parts, such as automotive engine blocks, cylinder heads, suspension components, aluminum wheels, electronic radiators, pump casings, impellers, and golf club heads. It’s suitable for parts requiring high precision and complexity.

What is the quality of low pressure castings?

The greatest advantage of low pressure casting is its ability to produce high-strength and high-precision castings. Precisely controlled filling processes reduce porosity and oxides, ensuring low defect rates and uniform mechanical properties.

Are low pressure casting products durable?

Yes. Low pressure casting reduces porosity and ensures excellent mechanical properties due to its low turbulence and high controllability. Durability also depends on material selection, design rationality, heat treatment, and actual operating conditions.

What is the accuracy of low pressure casting?

Low pressure casting offers higher precision than traditional gravity casting. The standard tolerance for products produced is set at ±0.005 inches for the first inch and ±0.003 inches for each additional inch.

What is the lifespan of low pressure casting products?

The mold life is typically between 80,000 and 100,000 cycles. The final product life varies depending on the material, workmanship, design, and operating environment. However, if the process is appropriate, the casting generally has excellent mechanical properties and low porosity, and can be used reliably for a long time.

Summary:

This article details the definition, history, principles, processes, equipment, advantages and disadvantages, and applications of low-pressure casting. It also compares the differences between low-pressure casting and high-pressure casting using a 13-point system. For more detailed information, please contact us and our professional engineers will answer your questions online.