What is stainless steel investment casting?

As the name implies, stainless steel investment casting refers to a metal forming method that uses stainless steel as a processing material and then uses an investment casting process to manufacture precision parts. This process is also called lost wax casting or precision casting. It is a manufacturing process based on wax molds, through ceramic cladding, high-temperature dewaxing and metal pouring, and finally obtains complex geometric metal parts.

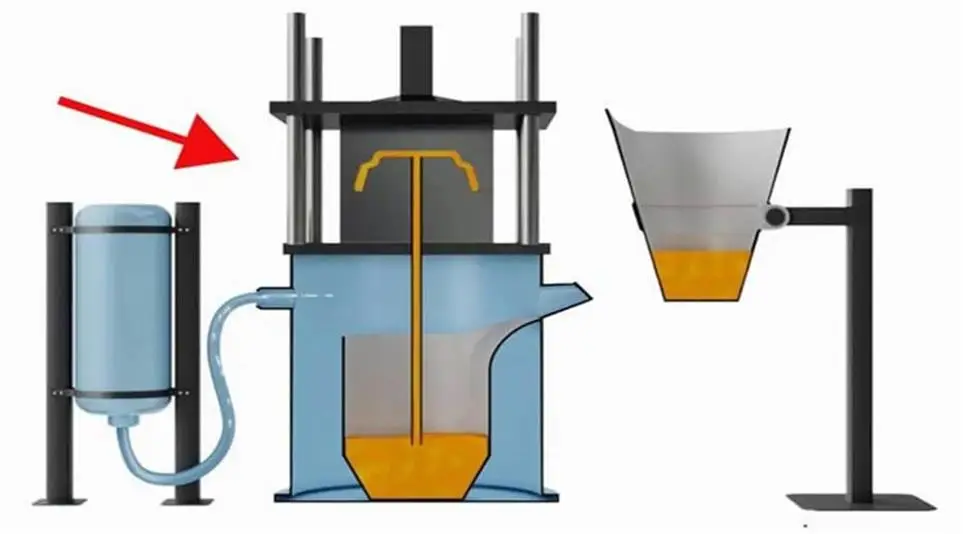

The process flow is roughly as follows: first prepare a wax mold consistent with the shape of the final part, then repeatedly apply ceramic slurry on its surface and sprinkle sand to form a ceramic shell, and then dewax it at high temperature after a period of drying. The purpose is to dissolve the previous wax mold, leaving only a hollow ceramic cavity, and finally pour the molten stainless steel metal into the ceramic shell, wait for cooling and solidification, and then break the shell mold, so that a stainless steel casting with precise size and complex shape is processed.

LVXUN has rich experience in producing large quantities of stainless steel investment castings. Our products are widely used in aerospace, shipbuilding, military and other industries. Welcome to visit our investment castings page, and you can also contact us online to ask what parts we can make.

Stainless steel materials have become a commonly used alloy material in investment casting due to their excellent corrosion resistance, strength and machinability. Compared with traditional casting methods, stainless steel investment casting can achieve

higher dimensional accuracy and surface quality. It is especially suitable for manufacturing parts with high requirements for appearance, performance and structural complexity. It is widely used in aviation, medical, food processing and other industries. The following will describe the advantages of stainless steel investment casting from the perspective of stainless steel materials and investment casting process.

Analysis of the advantages of stainless steel investment casting

Stainless steel investment casting combines the performance advantages of stainless steel materials and the forming advantages of investment casting process. The specific advantages are as follows:

(1) Process level:

High dimensional accuracy: Investment casting process is the process with the highest dimensional accuracy among casting processes including pressure casting, gravity casting and sand casting.

Complex geometric structure molding in one go: It can cast difficult-to-process structures such as blind holes, threads, cavities, thin walls, etc.

High surface quality: The surface roughness Ra can reach between 1.6 and 6.4μm. The lower surface roughness is conducive to reducing subsequent processing.

Near net shape, not too much material: Compared with machining, the casting process avoids a large amount of cutting material. This is beneficial in terms of saving material costs.

High production repeatability: Through modern high-tech systems, investment casting can achieve stable production in medium batches.

(2) Material level (stainless steel):

Excellent corrosion resistance: Stainless steel materials have excellent corrosion resistance and are particularly suitable for marine, food, chemical and other fields.

Good mechanical properties: high strength and hardness, good wear resistance.

Weldable, heat-treatable, and polishable: The performance of stainless steel investment castings will improve after heat treatment, and they have a high-quality surface after polishing.

High temperature resistance: Some stainless steels can be used in environments above 500°C.

Hygienic and aesthetic value: Stainless steel materials are widely used in medical, food and other fields that require hygiene. At the same time, its bright silver appearance is also conducive to its application in the decoration field.

Industries using stainless steel investment castings

High-quality stainless steel investment castings have higher corrosion resistance, better surface finish and better detail processing effects. The industries that commonly use stainless steel investment castings include the following, and some typical parts are listed after each industry. You can check whether the following industries or parts are what you need:

(1) Aerospace:

Fuel nozzles

Transmission system connectors

Turbine engine housing parts

(2) Automotive industry:

Exhaust manifolds

Turbocharger housing

Suspension connecting rod seat

(3) Food processing industry:

Valves and pump bodies

Agitator blades

(4) Seawater desalination and marine engineering:

Desalination pump impellers

Fluid equipment parts

Pipeline joints

(5) Pump and valve parts:

The parts of pump and valve products are mostly made of stainless steel parts because of their good corrosion resistance and economical price.

Pump housing

Impeller

Valve body and valve cover

(6) General machinery manufacturing:

Bearing seat

Bracket and connecting block

(7) Medical device field:

Surgical instrument parts

Joint implant skeleton

High-end dental equipment parts

(8) Mining equipment:

Wear-resistant joints

Conveyor hooks

(9) Petrochemical industry:

Pipe fittings tees

Heat exchanger connectors

High-pressure valve housing

(10) Agricultural machinery:

Sprinkler nozzles

Tractor connecting rods

Fertilizer distributor parts

The above are the industries and parts for most applications. If you are still not sure whether you should use stainless steel or investment casting to manufacture your parts, please ask our LVXUN professional engineers and we will answer you online.

Selection of commonly used stainless steel alloy grades for investment casting

Common stainless steel investment casting materials include multiple series of grades, which can be mainly divided into the following categories. Each type is suitable for different application scenarios according to its chemical composition and performance characteristics:

(1) Austenitic stainless steel (300 series)

This is the most common series of stainless steel casting materials. It has excellent corrosion resistance and good welding performance. It is usually used in environments requiring high corrosion resistance, such as food processing and chemical industries.

Representative grades include 304, 316, etc. Among them, 316 contains molybdenum and has stronger resistance to chloride corrosion.

(2) Ferritic and martensitic stainless steel (400 series)

This series of stainless steel has high strength and wear resistance, but its corrosion resistance is slightly lower than that of the 300 series. It is commonly used in automotive parts, knives, mechanical structures, etc.

Martensitic stainless steel, such as 410 and 420, can be heat treated to increase hardness, while ferritic grades such as 430 have good oxidation resistance and formability.

(3) Precipitation hardening stainless steel (PH series)

This type of material combines high strength and corrosion resistance. It is a type of martensitic stainless steel. It is hardened mainly by heat treatment. Common grades include 17-4 PH, 15-5 PH and 14-4 PH, among which 17-4 PH is more widely used.

(4) Duplex stainless steel (such as 2205)

Duplex stainless steel combines the microstructure of austenite and ferrite. It has excellent corrosion resistance and high strength. 2205 is a typical duplex steel. It is often used in oil and gas, chemical processing equipment and seawater environments. It can withstand harsh corrosive conditions.

The choice of material depends mainly on the use environment and performance requirements of the parts, such as corrosion resistance, strength or whether it can be heat treated.

What are the main costs of stainless steel investment casting?

(1) Raw material cost:

This is the largest item in the total cost, especially when using high-grade stainless steel (such as 316, 17-4PH), the unit price of the material is higher than that of other stainless steel.

(2) Mold manufacturing cost:

In the early stage, metal molds need to be made for the production of wax molds. The higher the precision of the mold and the more complex the structure, the higher the cost. If you want to reduce costs, you can use 3D printing to directly print the wax mold, which saves the cost of metal molds.

(3) Processing cost:

Including wax mold manufacturing, tree assembly, shell making, dewaxing, roasting, pouring, cooling, shelling, cutting and other processes. Each process is part of the cost expenditure.

(4) Equipment use cost:

Mainly used for smelting stainless steel, roasting ceramic shells, insulation, cutting and other processes, and also includes the investment in equipment such as coating ceramic slurry and adhesives.

The higher the requirements of the casting, the higher the cost of post-processing. The post-processing process mainly includes heat treatment, machining, surface polishing, sand cleaning, testing and other steps.

(5) Post-processing cost:

(6) Inspection and quality control cost:

We LVXUN have professional testing equipment, including dimensional inspection, non-destructive testing, chemical composition analysis, mechanical properties testing and other parts to ensure that the quality of the finished product meets customer requirements and market standards.

These aspects together constitute the total cost of stainless steel investment casting. You should know that cost input and product quality are positively correlated. Of course, the overall manufacturing cost can also be reduced by reasonably controlling each link.

Summary

LVXUN Stainless Steel Foundry is one of the largest stainless steel investment casting and processing manufacturing companies in China, focusing on providing customized casting solutions.

We have advanced casting design, full-system casting process management, a variety of post-processing options and professional testing equipment, which can accurately meet customer drawings and technical requirements, and support various material selections.

In addition, in order to meet the one-stop procurement needs of different customers, we also provide supporting services such as heat treatment, precision machining and surface treatment to help you save time and cost, so as not to choose multiple manufacturers for your parts, which is both time-consuming and risky.

Our mature production technology and perfect quality control have made us a trusted partner of many overseas customers. If you have stainless steel investment casting or other metal materials, other casting processes or cooperation intentions, please leave a message or contact us, our technical team will quickly provide you with professional services.