Aerospace Investment Castings: We Focus on Providing Quality Services

Based on strict performance and safety requirements, investment casting is widely recognized as a cost-effective method for producing various parts for the aerospace industry. It can produce parts of various complexities with durable and corrosion-resistant materials.

Aerospace investment castings can withstand extremely harsh operating temperatures and environments. LVXUN produces castings that meet AS9001 standards and have the characteristics of precision and near-shape.

Table of Contents

What is casting?

Casting is a manufacturing process in which molten metal is poured into a mold and cooled to obtain parts of a specific shape and size. This method is applicable to a variety of metal materials and can produce parts with complex structures and various shapes.

The main advantages of casting are strong forming ability, high material utilization rate, and batch production, especially for industrial parts that need to withstand extreme working conditions such as high temperature and high pressure. Among the many casting processes, investment casting is widely used in high-end manufacturing fields such as aerospace due to its high precision and good surface finish.

How are aerospace investment castings produced?

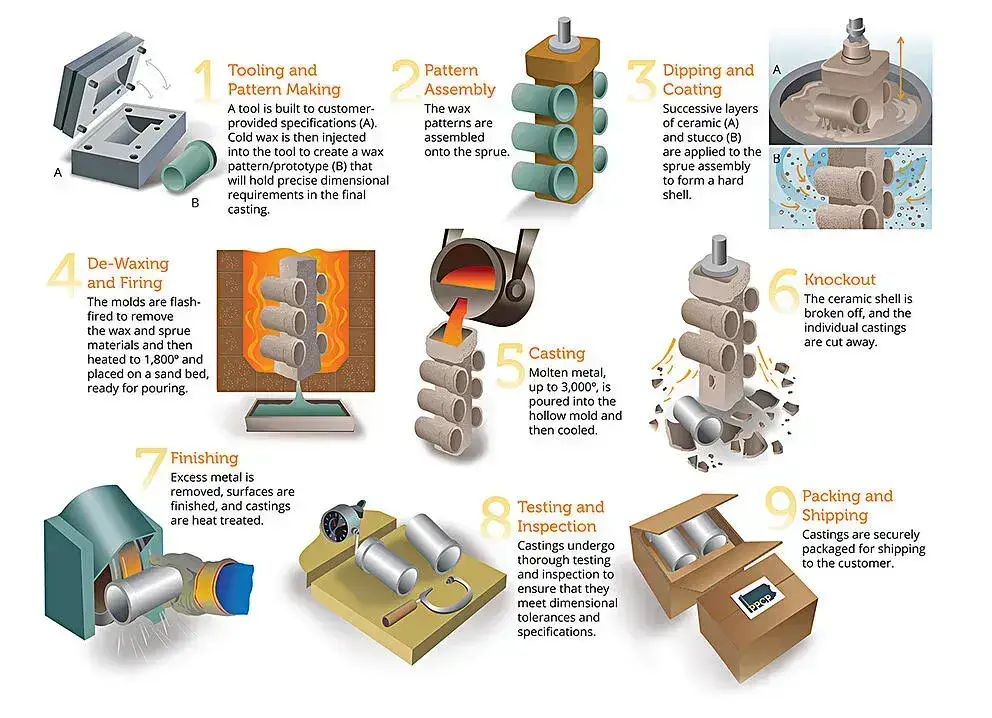

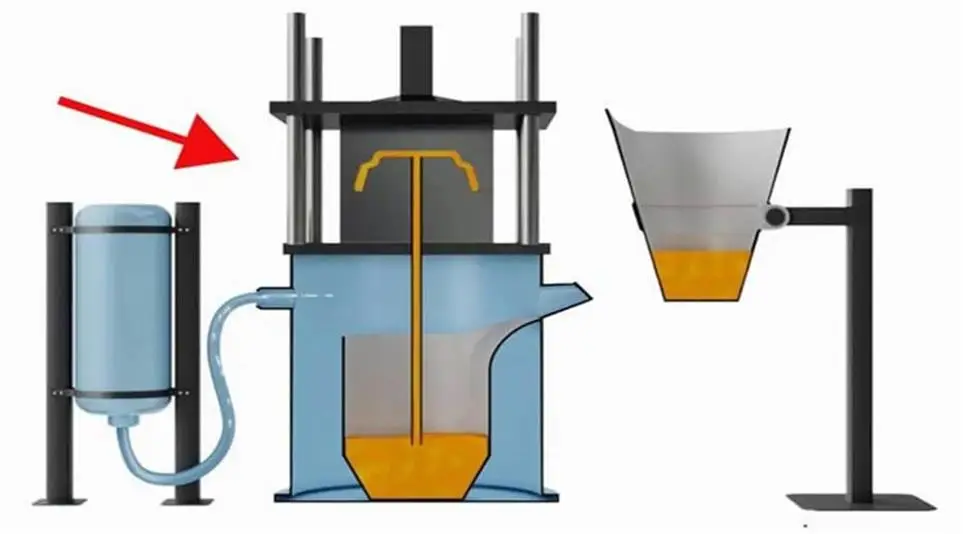

Aerospace investment castings are produced by the investment casting (lost wax casting) process, which is widely used in the manufacture of lightweight, thin-walled and complex aviation parts due to its high precision and complex forming capabilities.

The process includes wax pattern making, cladding, dewaxing, metal pouring and post-processing, which can achieve strict geometric tolerance requirements while maintaining excellent mechanical properties.

Compared with traditional processing methods, investment casting greatly reduces the amount of machining and improves material utilization. It is suitable for mass production of high-temperature and high-strength alloy parts. Its finished products are usually used in key structures such as engines and turbine blades, and are one of the indispensable technologies for aviation manufacturing.

The following is a detailed introduction to the machining process of aerospace investment castings:

┌────────────────────────────┐

│ 1. Wax Pattern Design │←—— CAD modeling based on aerospace component drawings

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 2. Wax Tree Assembly │←—— Assemble multiple wax patterns into a “tree” for batch casting

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 3. Shell Building (Slurry Coating) │←—— Repeated dipping and sanding to form a high-temp ceramic shell

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 4. Dewaxing │←—— Heat treatment removes wax to create hollow mold cavities

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 5. Shell Firing │←—— High-temperature firing strengthens the ceramic shell and removes residues

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 6. Metal Melting & Pouring │←—— Melt high-temp alloys (e.g., Ni/Co-based), pour under vacuum or inert gas

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 7. Cooling & Shell Removal │←—— Allow solidification, then break shell to extract the raw casting

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 8. Cutting & Cleaning │←—— Remove gates, risers, and excess structures

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 9. Heat Treatment & Straightening │←—— Improve microstructure and correct dimensional deviations

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 10. NDT & Dimensional Inspection │←—— X-ray, ultrasonic, CMM to detect defects and verify precision

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 11. Precision Machining (e.g. CNC) │←—— CNC machining for critical interfaces and tolerances

└────────────┬──────────────┘

↓

┌────────────────────────────┐

│ 12. Final Quality Check & Delivery │←—— Full inspection, packaging, and shipment to aerospace clients

└────────────────────────────┘

If your parts do not require finishing, the steps are usually as follows:

Aerospace investment castings mainly include the following types of parts, including but not limited to the following:

Turbine blades, turbine guide vanes (guide vanes)

Combustion chamber nozzles

Interior components

Hydraulic oil system components, fuel distributors

Engine bracket connectors

Landing and brake components

Flight critical and safety components

Supercharger housing

Turbine housing front section

Tail nozzle components

Propulsion system valve body

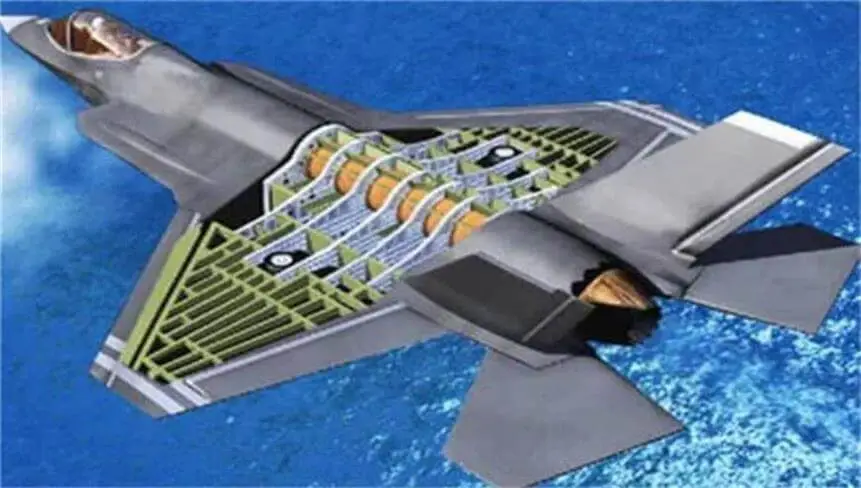

The key components in aerospace casting are aircraft engine parts, and the manufacturing of these engine blades, guide vanes, nozzles, combustion chambers and other components almost all require precision casting technology.

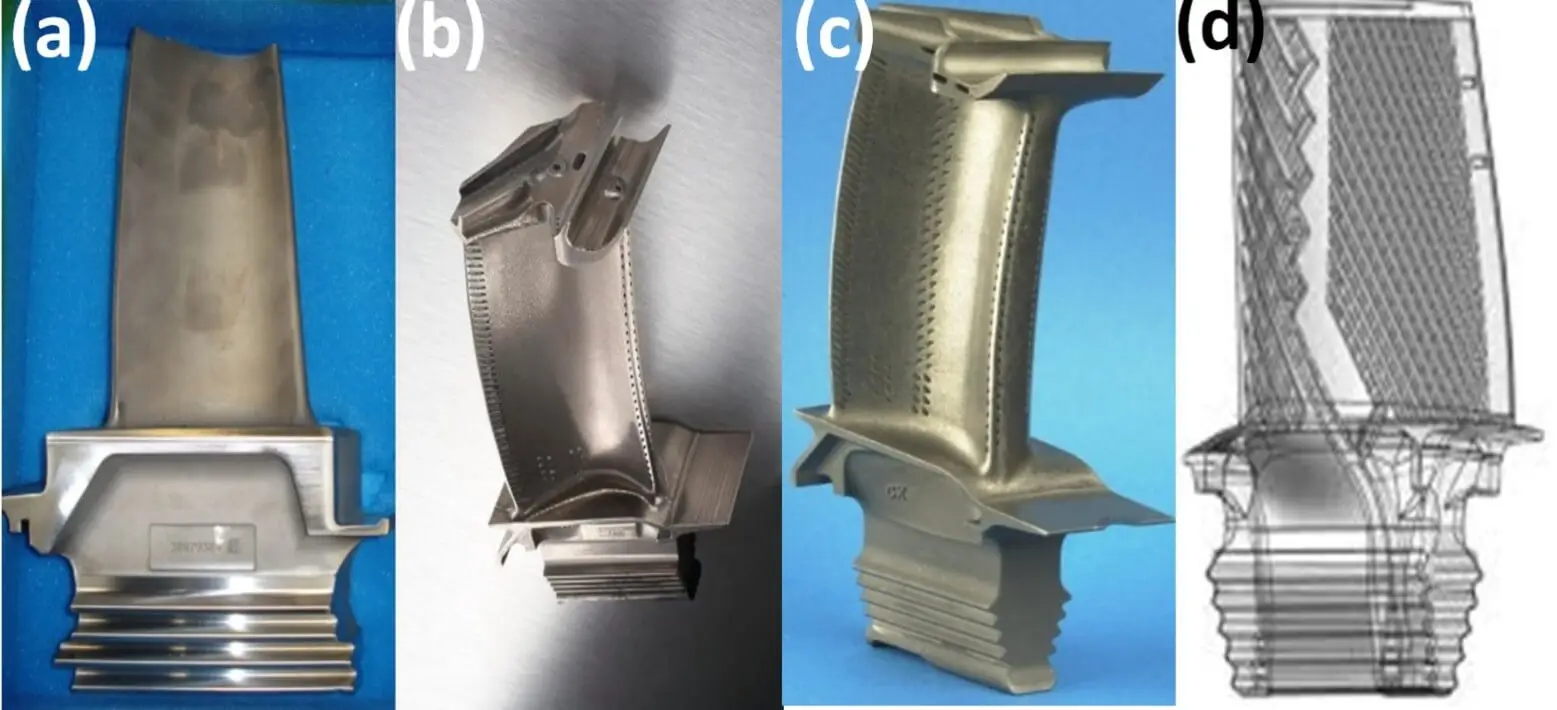

What are airfoil castings? What are they typically considered?

Simply put, airfoil castings are cast parts that resemble wings. They are most commonly used in aircraft engines and gas turbines, such as turbine blades, guide vanes, and compressor blades. They are called “airfoils” because their cross-sectional curves resemble those of an aircraft wing, allowing airflow to flow in the designed direction and at the designed speed.

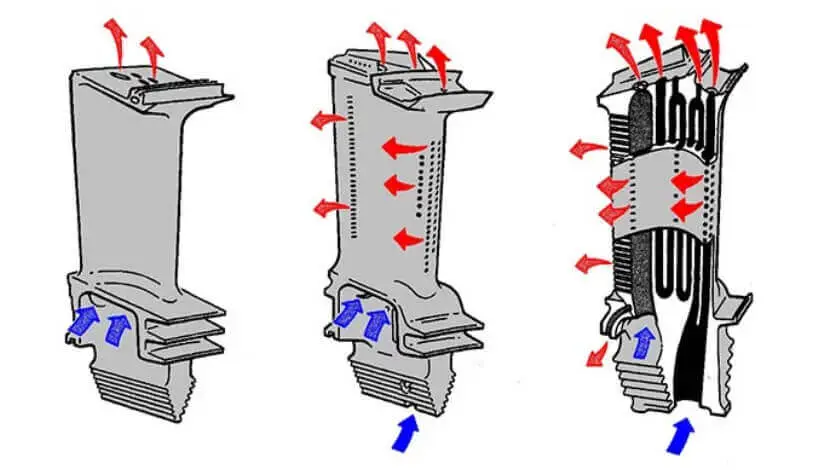

In engines, air or gas flows at high speeds and is continuously compressed, burned, and expanded. These blade-like parts are key components for guiding and supporting airflow. They must not only be precisely shaped to ensure aerodynamic performance, but also be robust, able to withstand temperatures exceeding thousands of degrees Celsius, extreme pressure, and long-term wear.

Airfoil castings are typically manufactured using investment casting, which can precisely reproduce complex streamlined shapes and thin-walled structures. High-performance materials such as nickel-based superalloys and titanium alloys can also be used. For turbine blades in high-temperature zones, more advanced directional solidification or single-crystal casting processes are required to strengthen the metal’s internal structure and resist deformation and failure in extreme environments.

LVXUN’s advantages in precision investment casting

Choose LVXUN as your aerospace investment casting supplier for the following reasons. Our team of experts is experienced and can provide the following solutions to meet your investment casting needs.

● We specialize in metal casting and provide customized design services oriented to customer needs;

● We have high-precision equipment to ensure the precise molding of complex geometric shapes and difficult parts;

● We have rich experience in mass production to meet the needs of orders of different sizes;

● We have a variety of material options, including nickel-based alloys and a variety of non-ferrous alloys, to meet the application requirements of multiple fields;

● We are also equipped with advanced CNC processing capabilities to achieve high-precision integrated processing of castings;

● We provide a one-stop solution for investment casting manufacturing;

● The team consists of experienced engineers, casting experts and technicians to ensure stable and reliable product quality;

● We are committed to providing customers with high-quality, high-performance castings to help reduce manufacturing costs and shorten delivery cycles.

Common investment casting alloys for aerospace applications

Common alloys mainly include aluminum, stainless steel, carbon steel, nickel-based alloys, cobalt-based alloys, etc.

Aluminum alloys

A356

A357

Nickel-based alloys

Inconel 600

Inconel 625

Hastelloy A

Hastelloy X

Stainless steel

17-4 PH

15-5 PH

347 Austenitic stainless steel

410 Martensitic stainless steel

421 Martensitic stainless steel

Carbon steel alloys

AISI 1020

AISI 1045

AISI 4140

Cobalt-based alloys

Cobalt 6 series

Cobalt 21 series

Cobalt 31 series

Investment casting materials are diverse, and investment casting also facilitates the use of lightweight and high-strength materials such as aluminum alloys and titanium alloys. This is crucial for aerospace and other industries where weight reduction is a top priority.

Why must aerospace parts be cast? Can’t they all be machined?

The core value of castings in aerospace manufacturing lies in: complex shapes + one-time molding + excellent material properties + reasonable cost control.

Complex and difficult processing: Many engine cases, turbine blades, etc. have hollow, internal flow channels, or large-size thin-walled structures. These structures are almost impossible to achieve through mechanical processing. If they are forced to achieve, it will only increase the difficulty and cost of processing.

Lightweight requirements: Casting can arrange the material only in the key stress area through the flow of molten metal, which will not destroy the function of the part itself and can also achieve the effect of reducing weight.

More reasonable cost and cycle: Compared with cutting from a whole piece of titanium alloy forging, casting has a higher utilization rate of raw materials and lower cost.

In short: Aerospace investment castings are the key forming method of “high performance + high cost performance”.

Obtain flawless aerospace investment castings

You can trust our mature casting process and post-processing process. By establishing cooperation with LVXUN, you can get the perfect, durable and high-precision castings required by the aerospace industry. In addition to being pollution-free and environmentally friendly, our process can also ensure that there are no defects and no casting marks.

FAQs:

What materials are commonly used in aerospace investment casting?

Common materials include nickel-based superalloys (such as Inconel, used in turbine hot ends), titanium alloys (used in compressor blades and structural components, offering an excellent strength-to-weight ratio), aluminum alloys (for lightweight structural parts), and stainless steel and high-strength alloy steels (for certain housings and fasteners). Different materials have different requirements for melting, molds, and heat treatment.

What dimensional accuracy and surface finish can investment castings achieve?

The dimensional accuracy of precision investment casting is generally much higher than that of sand casting. The specific tolerances and surface finish depend on the pattern, number of mold layers, material, and heat treatment. A common practice is to allow a small machining allowance and then refine critical mating surfaces through machining. The specific accuracy range should be discussed with LVXUN and confirmed based on the drawings.

What quality certification requirements must aerospace castings meet?

The aerospace supply chain often requires AS9100/ISO9001 systems, material-specific AMS/ASTM standards, and manufacturer’s process capability and inspection reports (chemical composition, mechanical properties, non-destructive testing records, etc.). Safety-critical components will also have strict batch tracking requirements.

Why do turbine blades use single crystal or directional solidification processes? What are they?

Turbine blades operate in high-temperature zones, and grain boundaries can become initiation points for high-temperature creep and cracking. Directional solidification (DS) and single crystal (SX) casting significantly improve high-temperature strength and creep resistance by controlling the solidification direction or eliminating grain boundaries. Therefore, they are often used in investment casting of high-temperature turbine blades. Process research related to directional solidification and single crystal casting is also a hot topic.

What are the key design considerations for design for manufacturability (DFM)?

The design should maintain a reasonable, uniform wall thickness or use gradual transitions to avoid extremely thin walls and sharp transitions; allow for machining allowances and clamping surfaces; design appropriate gate and riser locations for pouring and venting; account for heat treatment deformation and make dimensional compensations; and use casting simulations to verify pouring and solidification behavior early to reduce rework. Early communication with us can significantly reduce risk.

Which is better, investment casting or metal 3D printing (additive manufacturing)?

There’s no absolute advantage or disadvantage; the emphasis is on different aspects. Investment casting is more mature and cost-effective for small- to medium-volume complex parts and certain materials (especially alloys); additive manufacturing offers advantages for prototypes, extremely complex cavities, and rapid iteration. In practical applications, the two are often combined: 3D printing is used to create immersive patterns or verify complex internal coolant channel designs.

What are the key factors determining production costs and delivery times?

Key factors include: pattern preparation (wax or 3D printed), mold coating and sintering cycles, melting and pouring efficiency, post-processing (sand removal, heat treatment, machining, surface treatment), and rigorous inspection and traceability requirements. Aerospace-grade parts require higher testing and recordkeeping, which can increase both cost and delivery time.

What do you think?

[…] the casting requires high precision and surface quality, such as aerospace, medical equipment and other fields, investment casting should be selected; if the precision and […]